To create jewelry that’s durable, hypoallergenic, and affordable, different plating methods are used — but few match the performance of ion plated stainless steel jewelry. This advanced coating technique, often called IP plating, has gained attention for its exceptional resistance to tarnish and wear.

In this guide, we cover what ion plated jewelry is, whether IP plated jewelry tarnishes, and how ion plating compares to PVD and gold plating.

What Is Ion Plated Jewelry?

Ion plating (IP) jewelry is an advanced coating technique performed through a Physical Vapor Deposition (PVD) process, where metallic particles, such as titanium nitride, are vaporized and deposited onto a base material, usually stainless steel. This creates a durable, scratch-resistant surface that enhances both the appearance and longevity of jewelry.

It also allows for a wide range of IP plated colors depending on the coating material:

- Black ion plated stainless steel utilizes materials like titanium carbide to create its sleek, dark aesthetic

- Gold/yellow ion plated stainless steel uses titanium nitride to create a rich, yellow-gold appearance

Benefits of Ion Plating on Jewelry

Ion plating (IP) offers several advantages that make it a preferred coating method for modern jewelry manufacturing. Here’s why it stands out:

- Exceptional Durability

With just a thin coating, ion-plated jewelry achieves a hard, long-lasting surface that outperforms traditional methods like electroplating in scratch resistance and wear longevity.

- Low Maintenance & Water Resistant

IP coating on jewelry requires just a little maintenance. Unlike other plating techniques, you don’t need to worry about the effects of water.

- Luxurious Look at a Lower Cost

Ion plating allows jewelry to mimic the appearance of precious metals like gold, silver, or platinum—offering a wide range of colors and finishes without the high price tag.

Ion Plated vs Stainless Steel: Key Differences

When choosing jewelry, it’s important to understand the difference between ion plated jewelry and stainless steel jewelry. Here’s a quick comparison:

| Aspect | Ion Plated Jewelry | Stainless Steel Jewelry |

| Definition | Stainless steel coated with a thin layer of gold using ion plating. | Solid stainless steel without any coating. |

| Durability | Very hard and scratch-resistant coating. | Strong and corrosion-resistant base metal. |

| Color Options | Wide range of colors—gold, black, rose, blue. | Limited to natural silver-gray tones. |

| Resistance to Tarnish | Excellent. | Naturally tarnish-resistant. |

| Appearance | Luxurious, customizable finish with high shine. | Sleek, simple, and industrial look. |

| Best For | Premium, long-lasting, colorful designs. | Minimalist, durable everyday jewelry. |

In short, both ion plated and stainless steel jewelry are known for their strength and longevity, but they serve different purposes. Stainless steel is the base material, which is naturally durable, corrosion-resistant, and hypoallergenic. Ion plated jewelry, however, adds an extra layer of coating, such as titanium nitride or gold tone, over stainless steel, giving it enhanced scratch resistance and a more luxurious appearance.

While stainless steel alone offers a sleek, industrial look, ion plating provides design versatility and luxurious look, making it ideal for jewelry that needs both beauty and endurance.

Ion Plated vs PVD Plated Jewelry: Key Differences

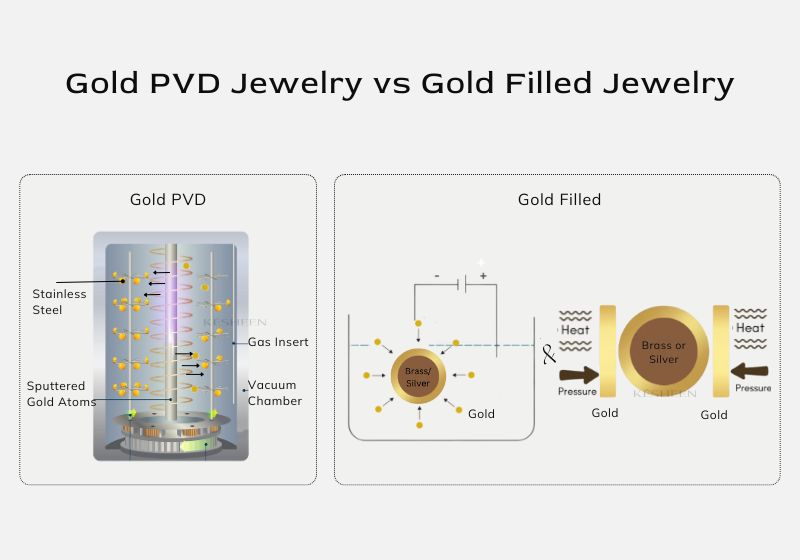

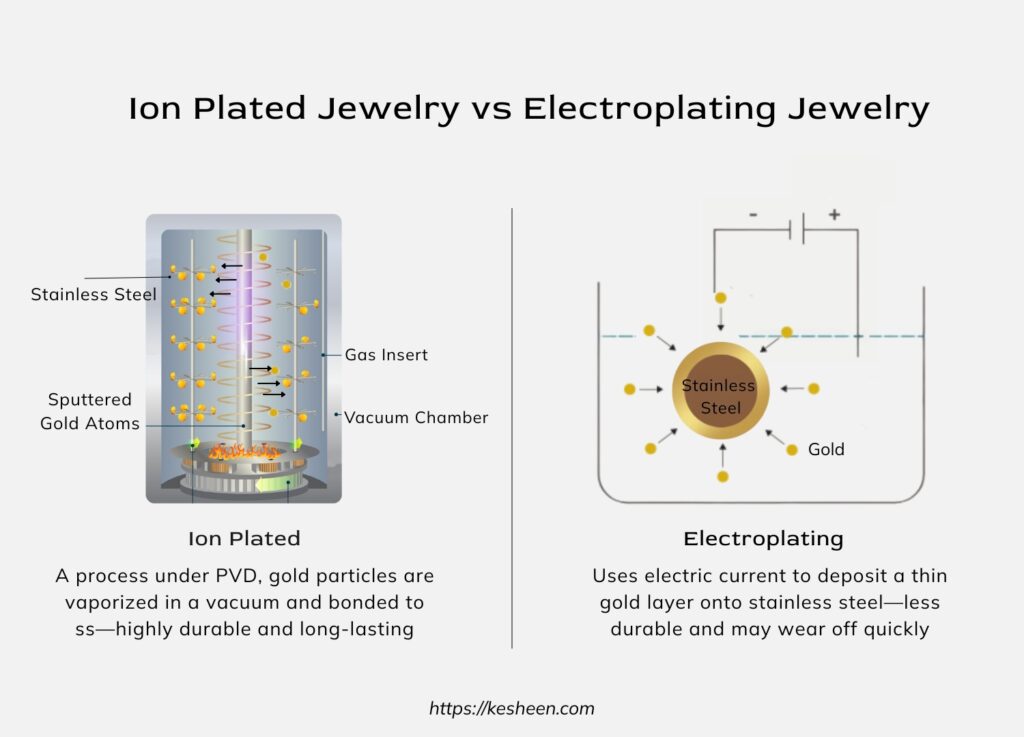

Actually, there is no major difference between ion-plated jewelry and PVD-plated jewelry. The only notable fact is that ion plating is a process under PVD (Physical Vapor Deposition).

Both techniques use the same principle of vaporizing a material in a vacuum and bonding it onto another material (usually stainless steel). Ion-plating also comes in different karat gold ranging from 10k to 24k to achieve varying hardness.

| Aspect | Ion Plated (IP) | PVD Plating |

| Definition | Same as PVD, ion plated is a process under PVD (Physical Vapor Deposition) | An umbrella term for vacuum-based coating methods, including sputtering, evaporation, and ion plating |

| Resulting Finish | High-quality, smooth, ultra-durable finish | Equally high-quality |

| Consumer Experience | Durable, tarnish-resistant coating available in various colors | Same—any difference is mainly technical |

| Practical Difference | None noticeable for jewelry brands and wearers | Also none |

PVD Ion Plating Process

PVD Ion Plating is a multi-step process that creates a thin, adherent coating on stainless steel. Below is a breakdown of how PVD ion plating works:

- Vacuum Deposition

The stainless steel is cleaned thoroughly to remove any dirt or adhesive on it. Then, it is inserted into a sealed vacuum chamber for precise control over the PVD ion plating process. Vacuum deposition eliminates contamination from outside components, allowing for high purity and coating quality.

- Sputter Deposition

Involves putting the stainless steel and the coating material in the vacuum chamber. The coating material is bombarded with high-energy ions, which causes the atoms from the material to be ejected into the vacuum chamber. Then, these atoms begin to deposit on the stainless steel.

- Arc Vapor Deposition

This process is done to further ionize the coating material to produce a thick coating quality. An electric arc is applied on the coating material, resulting in a high ionized metal vapor plasma. The metal ions created during this are directed toward the stainless steel, making the coating firmer and stronger.

- Ion Plating

This is the final ion plating process. It integrates the vaporization and ionization mechanism to ensure the coating material is tightly glued to the stainless steel.

Ion Plated vs Gold Plated: Is Ion Plating Better than Gold Plating?

Ion plating (IP) is commonly used on stainless steel jewelry, while gold plating usually refers to electroplating a thin layer of gold on metallic substrates like brass or silver, the traditional way.

Overall, ion plated stainless steel jewelry offers superior durability, scratch resistance, and long-lasting color, making it a more practical and visually appealing choice than traditional gold plating.

PVD Ion Plating vs Electroplating

Here is an in-depth comparison of IP plating jewelry vs electroplating (gold plating).

| Feature | PVD Ion Plating | Electroplating |

| Durability | Very high—scratch and wear resistant | Moderate for stainless steel |

| Hypoallergenic | Yes | Yes |

| Cost | More cost-effective in scale production | Typically higher for stainless steel |

| Environmental Impact | Cleaner process, minimal waste | Safe if controlled, but involves wastewater steps |

Durability

PVD Ion Plating: Creates a tough, resilient surface with titanium nitride layers, resulting in superior hardness and long-lasting performance on 316L stainless steel jewelry.

Electroplating: Coatings are softer and more prone to wear, exposing the base metal over time, especially on stainless steel.

Cost

PVD Ion Plating: Despite requiring specialized vacuum equipment, PVD is more cost-effective than electroplating for stainless steel, especially in higher volumes.

Electroplating: More expensive on stainless steel due to complexity and additional procedures to achieve reliable adhesion.

Environmental Impact

PVD Ion Plating: Generally cleaner, with fewer waste and no hazardous chemical discharge.

Electroplating: Environmentally safe when controlled, but requires wastewater treatment to manage chemical residues.

Color

Ion plating process can be used to create a wide variety of colors and finishes, such as gold, rose, black, or blue. You can have different levels of shine, from matte to high polish. However, some color combinations are difficult to create because of the complexities in the production process.

Electroplating can be used to mimic all types of colors and finishes. The production process is flexible, allowing you to achieve any jewelry appearance and meet your needs.

How Long Does Ion-Plated Jewelry Last?

Ion plated stainless steel jewelry generally lasts at least 2 years, and often much longer with proper care. The ion plating process forms a strong bond between the coating and stainless steel surface, creating a dense, wear-resistant layer that protects against scratches, fading, and tarnish. This durability allows ion plated jewelry to maintain its color and shine far better than traditional plated pieces.

Does Yellow Ion Plated Stainless Steel Jewelry Tarnish?

No, yellow or gold ion-plated stainless steel jewelry is highly resistant to tarnishing. Thanks to the molecular bonding in the PVD ion plating process, the yellow coating remains vibrant and glossy for years, even with daily wear. Minimal maintenance, such as gentle cleaning and avoiding harsh chemicals, helps preserve its finish.

Is Gold Ion Plated Real Gold?

Gold ion plated jewelry is not solid gold, but it uses a thin layer of real gold—typically titanium nitride in a gold tone—applied via PVD ion plating over stainless steel. While it offers the look of real gold, it’s more affordable, durable, and ideal for those seeking gold-tone jewelry that won’t tarnish easily.

Conclusion

Choosing the right type of jewelry plating plays a key role in how long your pieces last and how well they maintain their shine. Ion-plated stainless steel jewelry offers the perfect balance of durability, affordability, and style.

Partnering with a custom stainless steel jewelry manufacturer ensures your pieces are crafted with advanced ion plating technology for long-lasting color, superior wear resistance, and timeless beauty.

FAQs

Yes. Ion-plated jewelry is durable, scratch-resistant, and long-lasting. With vibrant colors and minimal maintenance, it offers a high-quality, stylish finish, making it an excellent choice for everyday wear or fashion jewelry collections.

Yes. Ion-plated stainless steel jewelry is generally nickel-free and suitable for sensitive skin. The PVD coating creates a protective layer that reduces allergic reactions, making it safe and comfortable for most wearers.

No. Black ion-plated stainless steel is highly resistant to tarnishing. Combined with stainless steel’s natural corrosion resistance, the IP plating process creates a durable coating that maintains its luster for years with proper care.