Every jewelry lover seeks attractive pieces that last long. Hence, custom jewelry manufacturers are saddled with the responsibility of fulfilling these needs by using PVD, which is a high-tech process that involves coating jewelry pieces with a thin layer of sparkling, stronger metals, like stainless steel.

While electroplating can also be used to achieve this process, the jewelry ends up tarnishing and fading over time. But PVD creates much more durable jewelry that can withstand extreme conditions.

What is PVD Coating on Jewelry?

PVD (Physical Vapor Deposition) coating is an advanced technique that involves applying a thin layer of metallic particles onto the surface of stainless steel jewelry.

This is done by placing the jewelry into a vacuum chamber that’s sealed airtight for efficient deposition coating without interference from air molecules. It results in a visually appealing piece that is extremely difficult to remove, making the stainless steel jewelry highly resistant to wear and tear.

PVD coatings come in a variety of colors, such as rose, white, and black. Manufacturers and jewelry enthusiasts often love PVD-coated pieces because of their incredible inert toughness against damaging elements, resistance to sweat, and compatibility for everyday wear.

Jewelry PVD Coating Process

Jewelry PVD coating involves sustainable production methods that are divided into 6 simple parts. They are explained below:

1. Loading and Pre-Cleaning

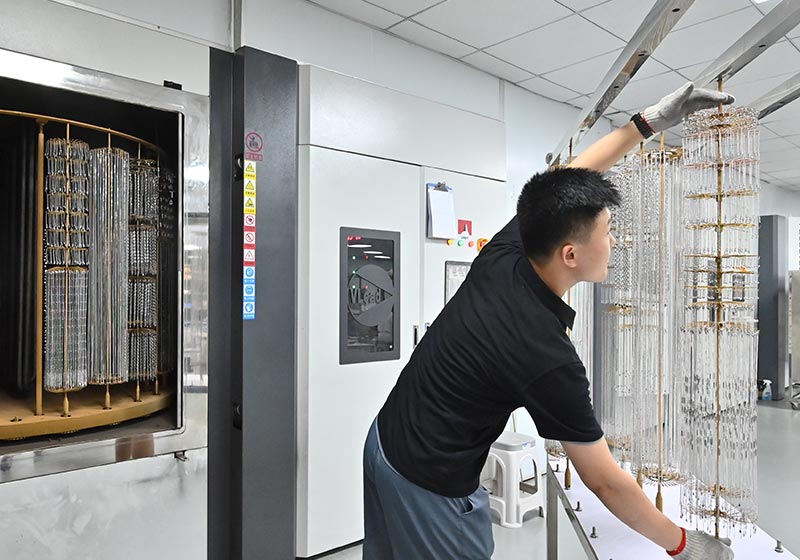

The jewelry pieces are carefully placed on a specialized stand inside the PVD chamber. The placement is important to ensure even coating and uniform coverage of all parts of the jewelry.

Afterwards, they are put under a thorough cleaning process to remove any impurity that could affect the adhesion and quality of the coating. The cleaning process typically entails multiple rounds of mechanical cleaning and chemical cleaning.

- Mechanical cleaning: Involves using highly pressurized air directed to the jewelry surfaces to remove dust and loose particles. It basically erases surface contaminants and creates a clean base for the coating.

- Chemical cleaning: Involves dipping the jewelry in specialized cleaning solutions, formulated to dissolve and remove oils, fingerprints, grease, and thick residues from the jewelry surfaces.

2. Drying and Degreasing

After the jewelry pieces are cleaned, they are dried because moisture interferes with the coating process. Generally, a combination of heat and vacuum is used to achieve this. While heat helps to evaporate the remaining water molecules, the vacuum removes the moisture from the PVD chamber, leaving the jewelry surfaces completely dry.

Sometimes, additional degreasing steps are required to eliminate lingering impurities, especially oil and grease that survive the cleaning process. In cases like this, degreasing the jewelry is essential to achieve a flawless and durable coating.

3. Loading and Final Preparation

The jewelry is arranged back on the stand within the PVD chamber. Ensure that they are positioned properly and there’s no chance of falling off during the coating process.

Depending on the desired effect you want to achieve, the jewelry might need to undergo extra preparatory procedures. For example, precise coating patterns like specific areas might need to be masked off. This ensures that only the intended parts of the jewelry are coated, guaranteeing the production of neat and pristine pieces.

4. Vacuum Sealing and Evacuation

At this stage, the PVD chamber is securely sealed to create an airtight enclosure. This tight sealing prevents external air from entering the chamber during the coating process.

Once sealed, the air captured in the chamber is slowly evacuated, creating a high vacuum environment. This disallows any potential interference from air molecules.

5. Coating Deposition

After sealing the vacuum and evacuating the air, the actual coating deposition begins.

It starts with using your chosen PVD method, such as magnetron sputtering to vaporize the target coating material like titanium nitride for black PVD.

Then, the vaporized particles are attracted to the negatively charged jewelry pieces within the chamber. This causes the particles to bond with the jewelry surfaces, forming a thin and uniform coating layer. All the jewelry within the chamber are exposed to this impact equally, resulting in consistent coverage and adhesion.

Although, while the process is going on, the thickness of the coating and other parameters like the deposition rate and temperature must be monitored and controlled to prevent irregularities. Doing this enables you to have final coated jewelry pieces that meet the specified quality standards and aesthetic demands.

6. Unloading and Finishing

Once the coating deposition is finished, the chamber is carefully vented to allow air to cool the jewelry. Then, the jewelry are gently removed with precision to avoid any damage to the newly applied coating.

The finished pieces might undergo a final inspection to certify the coating uniformity and all-round quality. Any irregularities noticed are immediately rectified.

Finally, to have a flawless and consistent finish, the coated jewelry will be polished. This smoothens out any surface inconsistency, as well as boost the shine and look of the jewelry.

Is PVD Plated Jewelry Good?

PVD coating offers good, smooth, durable, long-lasting jewelry pieces with a superior finish and color options. Here are some of the most important features:

- Smoother Coating Surface: When compared to other coating techniques like electroplating, PVD plated jewelry has smoother coating surfaces with a better appearance and feel.

- Enhanced Thickness: PVD-plated jewelry is bonded with thick layers of metals, evenly distributed to the whole surface. This makes them scratch-resistant, and corrosion-resistant, thereby preserving their longevity and aesthetics.

- Long-lasting: The advanced technique used in PVD ensures that the coating adheres firmly to the jewelry surface, resulting in a piece of highly durable jewelry that can last for years. This promotes responsible consumption and reduces frequent replacements.

- Better Color Effect: PVD supports a variety of color options with vibrant finishes. The coating process involves precise control, resulting in jewelry pieces with striking color effects. Generally, the applied layers make your jewelry shine extraordinarily and improve your appearance.

- Environmentally friendly: All PVD-plated jewelry, including women’s necklace and stainless steel ring for men are manufactured via sustainable and pollution-free methods. The process doesn’t include damaging chemicals like cyanide, which is often used in making other jewelry.

Are there Other Plating Techniques for Stainless Steel Jewelry?

Yes, aside from PVD plating, there is another technique for plating stainless steel jewelry, which is water plating.

Water plating, sometimes called water-based electroplating or aqua plating, is similar to PVD plating in its manufacturing process, as it doesn’t make use of hazardous chemicals and solvents. It uses a more eco-friendly option, which is water-based solutions.

The plating procedure starts by cleaning the stainless steel jewelry to remove all dirt and impurities. Then, the jewelry are immersed in an electrolyte solution containing dissolved metal ions, such as gold, silver, or platinum. After that, a direct electrical current is passed through the solution, making the metal ions to bond with the jewelry surfaces. Once the required thickness of coating is achieved, the jewelry are removed, rinsed, and dried.

While it’s a good technique, the quality of the finished products isn’t usually perfect compared to PVD plating. Water-plated jewelry is not very durable and resistant to wear. Also, the color options are limited, as they cannot be customized into multiple colors and finishes.

Does PVD Jewelry Tarnish? Is PVD Coating Long-lasting?

No, PVD jewelry does not tarnish easily. Unlike other coated jewelry, PVD jewelry involves the bonding of thicker metals to stainless steel, thereby forming a hard surface that’s resistant to abrasion, wear, and tear.

The additional layer applied on PVD jewelry serves as protection against damaging effects caused by exposure to air, moisture, or chemicals. This ensures that the jewelry lasts long without deterioration.

Can You Shower with PVD Coated Jewelry?

Yes, you can shower with PVD coated jewelry without worries that they will get damaged. This is because they are resistant to water, as well as mild soaps, gels, and shampoos that you might use when bathing. But remember do not soak them on water on a long time.

However, do not wear your PVD coated jewelry when entering the pool or ocean because they are often treated with chemicals like chlorine, which are hazardous to jewelry. Chlorine and saltwater cause jewelry to tarnish and lose their luster as time passes.

How Long Does PVD Coating Last on Jewelry?

The lifespan of PVD coating on jewelry is dependent on certain factors, which are:

- Coating Quality: This refers to the thickness and precision of the coating. Lightly applied coatings have limited ability in resisting extreme conditions, thereby may not last long compared to PVD jewelry with very thick coating.

- Material Used: The type of metal used also determines how strong and durable the PVD jewelry will be. Stainless steel is the most durable and suitable metal for PVD coating.

- Intensity of Use: How often the jewelry are worn and the conditions they are exposed to can influence their durability. Everyday wear PVD jewelry exposed to extreme conditions will most likely deteriorate earlier than PVD jewelry that are worn only on special occasions.

However, professionally designed PVD jewelry can last for at least 2 years if maintained properly.

Does PVD Plating Wear Off or Peel Off?

No, PVD plating does not wear off or peel off easily. The manufacturing process involves tight adhesion of protective metal layers on the jewelry surfaces. Stainless steel, the most popular metal used by professional stainless jewelry manufacturers like Kesheen, is naturally strong and resistant to wear, tear, and abrasion. It can retain their original appearance despite coming against coarse elements.

However, the certainty of your PVD plating not to wear off or peel off also depends on the maintenance. Regularly clean your jewelry and don’t expose them to hazardous chemicals.

Is PVD Coated Jewelry Safe?

One of the common questions people ask is: “is PVD plating toxic to human?”

No, PVD plating is not toxic to humans. In fact, PVD-coated jewelry is one of the safest choices you can make when choosing your preferred jewelry designs. The metal layers deposited on PVD-plated jewelry are hypoallergenic i.e., they can be confidently worn by everyone, including people with sensitive skin without worrying about any adverse effects.

Generally, PVD-coated jewelry is safe. They don’t cause irritation or allergic reactions, making them ideal for individuals who love to accessorize without compromising comfort.

More about PVD Gold Plating on Jewelry

Among the common metals used for PVD is gold. Let’s briefly share some insight on PVD gold-plated jewelry:

Is PVD Gold Plating Good?

Yes, PVD gold plating is very good, hence why it’s commonly used by most manufacturers. Typically, it involves using the PVD process of vacuuming technology to apply a thin layer of gold onto jewelry surfaces.

Unlike gold electroplating, PVD gold plating is more durable and resistant to wear, which is why it’s commonly preferred by individuals seeking long-lasting and low-maintenance gold jewelry.

Is Gold PVD Coating Real Gold?

Gold PVD coating deposited on jewelry surfaces may or may not be real gold. The option of using real gold or not is made by customers’ preference and budget.

Sometimes, customers only want gold because of the color and beauty. In these cases, fake gold PVD coating can be used as long as it sparkles and shines radiantly. Also, real gold can be expensive, so if the customers are constrained by budget, a normal yellow color metal that looks like gold can be used.

Key Takeaway

PVD coating jewelry isn’t just a fashion statement. It is a long-lasting and safe jewelry design ideal for people who want a beautiful piece that can be worn every day without compromising its brilliance and shine.

We hope that with this article as a guide, you can make informed decisions about how a properly made PVD coated jewelry should appear and rest assured that it won’t cause allergies nor tarnish over time. And if you need more information or would like to PVD coat your stainless steel jewelry, you can contact us. Our experts are readily available to attend to you.