For jewelry brands, PVD coating thickness for jewelry is one of the most common concerns. How thick should the coating really be? Does “thicker” always mean better? This article explains the essentials of PVD coating thickness, helping jewelry brands make informed decisions that balance quality, durability, and cost while ensuring their pieces meet customer expectations.

What Is PVD Coating on Stainless Steel Jewelry?

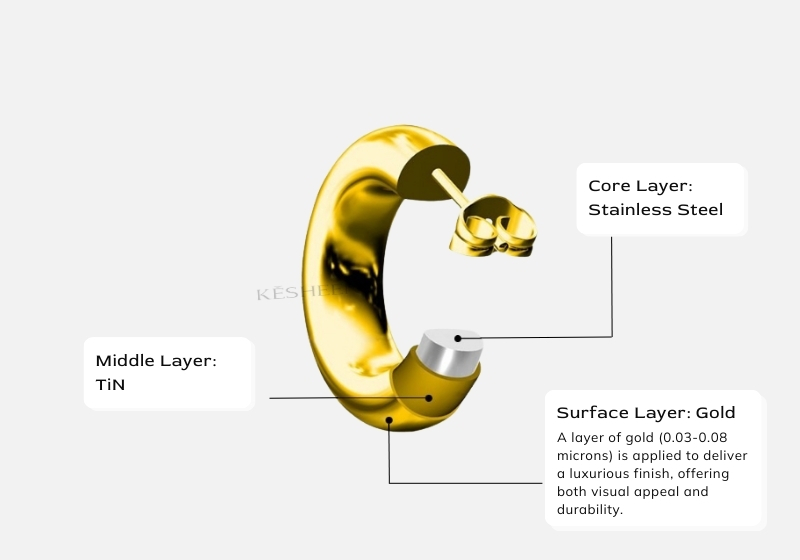

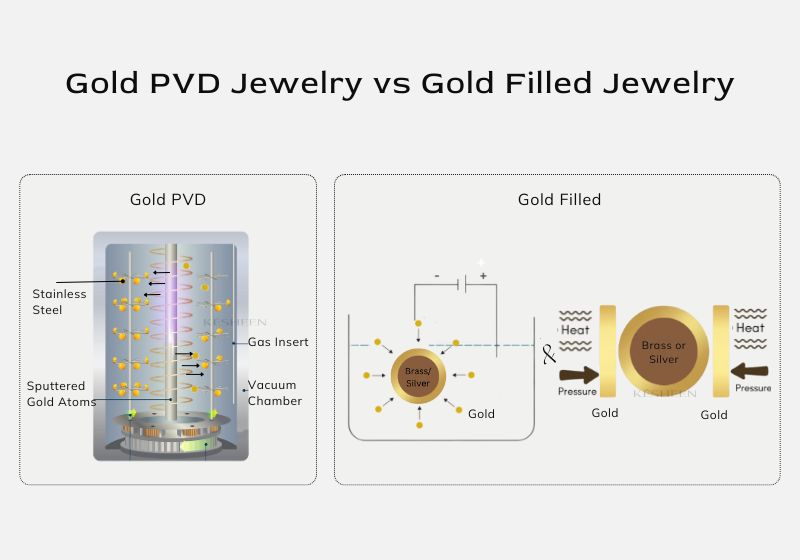

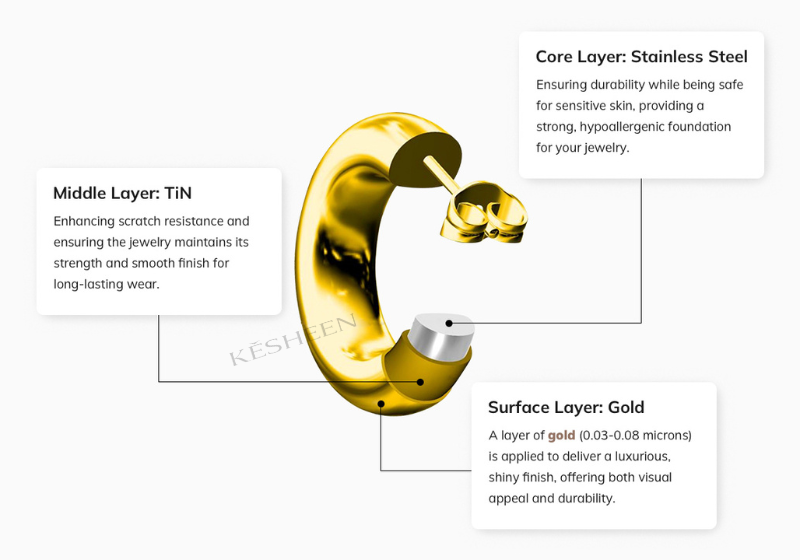

PVD stands for Physical Vapor Deposition. It is a coating technique where a thin layer of gold is vaporized in a vacuum chamber and deposited evenly on the surface of stainless steel jewelry to create a durable, hypoallergenic, and corrosion-resistant finish. To learn more, explore our detailed insights on PVD coating jewelry.

Thickness plays a key role here: it determines how well the layer bonds with the jewelry base, how long PVD jewelry can last, and whether it offers a cost-effective solution for your brand.

Standard PVD Coating Thickness For Jewelry

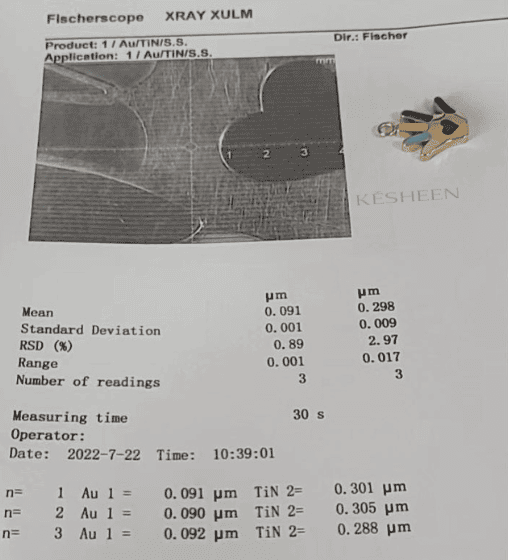

The common thickness for PVD coating jewelry typically ranges from 0.03 to 0.08 microns. This range is well-regarded in the industry, offering an excellent balance of durability and cost-effectiveness.

This PVD coating thickness for jewelry can withstand daily wear and tear, and with proper care, it can last for at least 2 years. For most brands, especially those focusing on trendy, accessible collections, this standard thickness meets the market’s demand for both quality and value.

Premium PVD Coating Thickness For Jewelry: When to Consider

For brands that prioritize exceptional quality and a premium feel, opting for a higher PVD coating thickness (0.08-nearly 0.1 microns) on stainless steel jewelry is a worthwhile investment. At this level, the finish provides exceptional resistance to wear, longer-lasting shine, and superior color retention, all of which strengthen the perception of quality.

However, this comes at a higher cost. Brands that invest in 0.08 to nearly 0.1 micron PVD coatings on jewelry usually target customers who value longevity and premium craftsmanship. It’s less about short-term affordability and more about reinforcing brand identity and building customer trust with superior quality.

Why Is Jewelry PVD Coating Thickness Not Recommended to Go Too Thick?

A common misconception is that thicker plating automatically means better quality. In fact, unlike electroplating, where the plating thickness can be much thicker, PVD coating is not ideal for going too thick.

If the coating gets too thick, adhesion between the coating layer (such as the titanium nitride layer, the gold layer) and the jewelry base metal weakens. This results in poor bonding, increasing the risk of peeling or flaking over time.

Not all manufacturers even have the technical skill to achieve stable results near 0.1 micron. Our factory has the expertise to meet the recognized standard and, when required, reach nearly 0.1 micron without compromising adhesion. For brands that want assurance, we can also provide lab test reports to verify thickness and performance.

Choosing the Right Thickness for Your Brand

The right PVD coating thickness for your jewelry and brand depends on your target market, price point, and quality aspirations.

- For most fashion-forward brands focusing on style and affordability, the standard range of 0.03-0.08 microns offers excellent performance without over-investing in coating costs.

- For premium and luxury collections where longevity and color brilliance are critical, or brands with the aspiration of improving quality and brand image, higher coatings from 0.08 to near 0.1 microns provide a durable finish that maintains quality over time.

If you’re unsure which thickness suits your brand, working with a trusted custom jewelry manufacturer gives you expert guidance and support to meet your brand’s durability expectations while managing costs effectively.

Conclusion

PVD coating on jewelry relies on carefully balanced thickness to achieve durability and beauty. For most brands, 0.03–0.08 microns offers the ideal solution, while premium collections may benefit from 0.08-0.1 microns. Choosing wisely and working with the right partner ensures your jewelry performs beautifully in the market.