As technology advances across every aspect of life, the traditional methods of manufacturing jewelry are being complemented and replaced by cutting-edge solutions. One of such solutions is laser cutting technology, which combines the precision of lasers for cutting precious metals and the artistry of jewelry making.

Source: Pinterest

This blog post will familiarize you with what jewelry laser cutting is, as well as how it works. We’ll also explore its advantages and differences from other methods of cutting jewelry.

What is Laser Cutting in Jewelry Making?

Laser cutting for jewelry making involves a concentrated high-energy laser beam directed onto the surface of a material. The laser produces heat that melts the material, creating a clean, precise cut.

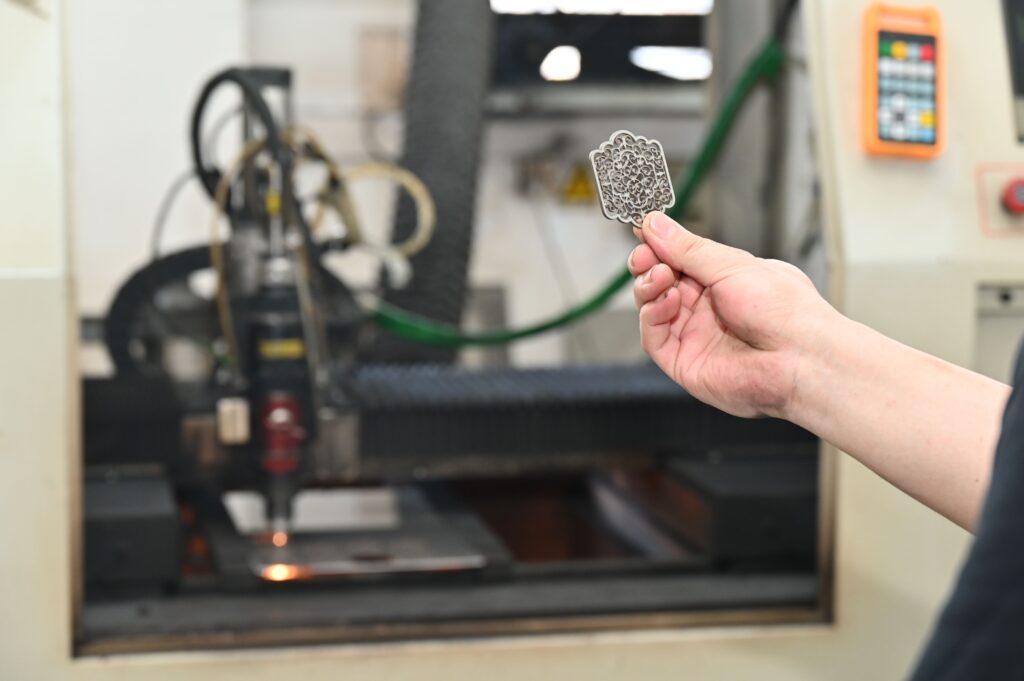

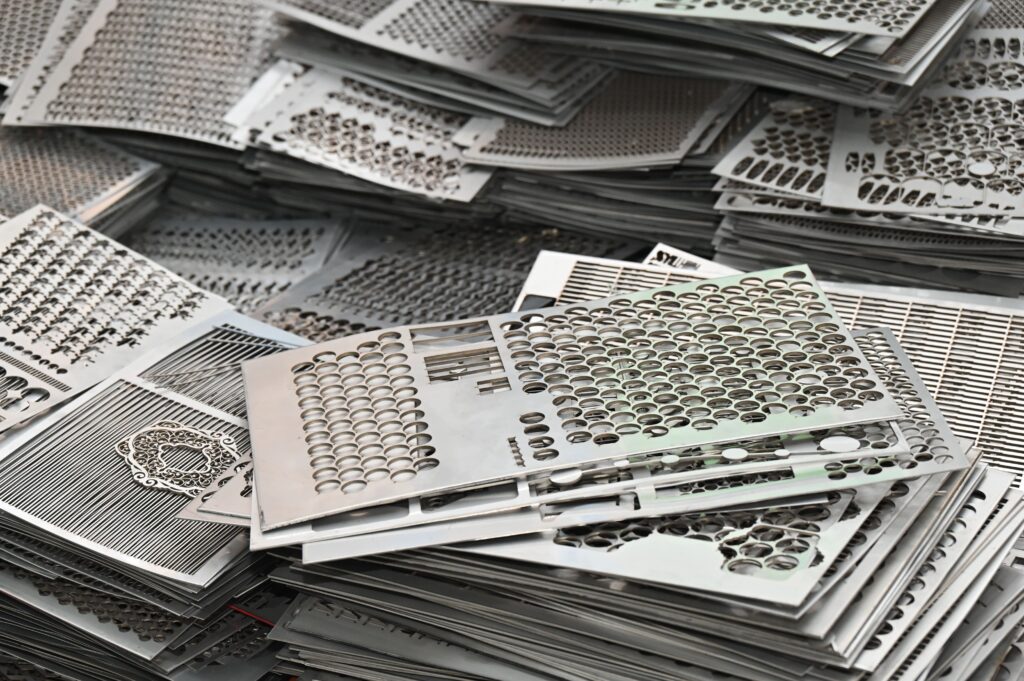

This technology allows for multiple pieces of jewelry materials to be cut quickly, with every piece looking the same. Due to its high level of precision, laser cutting enables designers to create intricate pieces and high-quality jewelry.

What Can Laser Cutting Technique Be Used for in Jewelry?

The laser-cutting approach processes various types of materials, which enables the production of a wide range of jewelry designs, including custom laser cut jewelry. Here are some techniques for making stainless steel jewelry as well as other complex designs:

Create and Cut patterns, shapes

Laser cutting is a cost-effective method for creating and cutting jewelry into simple and relatively complex designs, of various shapes and sizes. Some of these include heart shape designs, circle monograms, name necklaces, pendants and charms, etc

Jewelry laser cutting employs high-intensity beams that focus on specific areas to be cut. This results in limited material deformation, resulting in finely cut jewelry.

Create Hollowing-out Feature Designs

Different kinds of automatic cutting machines are available to make a bold cut or a delicate hollowing-out effect. These machines precisely vaporize the material surface to create hollows in earrings, bracelets, necklaces, and pendants.

Using laser cutting techniques, a custom jewelry manufacturer can easily produce detailed and challenging designs that involve hollow features without the constraints of traditional methods.

Precise Engraving

Another important usage of laser cutting is for engraving names, initials, dates, logos, or other personalized elements on jewelry. But, how accurate is laser cutting in engraving?

In contrast to traditional cutting techniques that result in rough finishes, laser cutters are computer-aided. This ensures unparalleled accuracy during the engraving of the most intricate designs. Their intense laser beams penetrate the workpiece cleanly and offer maximum precision on metal and non–metal materials, including laser cut stainless steel.

What Jewelry Materials Can Be Laser Cut?

Laser cutting is a versatile and precise method used by every modern stainless steel jewelry manufacturer to make jewelry. This technique allows the production of an extensive variety of materials. Here are some materials for making laser-cut jewelry:

Source: Pinterest

- Metals: Gold, silver, platinum, stainless steel, and titanium are laser-cut to create one-of-a-kind jewelry designs due to their malleability and durability.

- Non-metals: Traditional cutting methods for non-metals are time-consuming and require advanced skills. Laser-cutting machines ensure a convenient process when cutting and engraving crystals, gemstones, wood, leather, and acrylic materials.

Common Types of Laser Cutting Machines

The two main types of laser cutting machines are CO2 Lasers and Fiber Lasers, with each type designed to cut a specific type of material. While CO2 lasers are best for cutting and processing non-metals, fiber lasers are faster and suitable for hard-to-cut metals.

How Does Laser Cutting Work in Manufacturing Jewelry?

From making bespoke necklaces and bracelets to creating interlocking monogram patterns, laser cutting assures a cleat-cut outcome. Here’s a step-by-step process for laser cutting jewelry production:

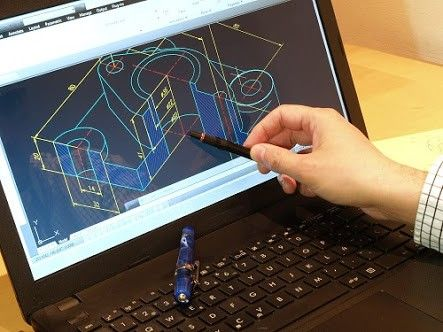

Step 1: Design and CAD Creation

The first and most important step is to know what design and type of jewelry to create. Using CAD programs, such as AutoCAD and fusion360, you can create the jewelry design. Afterward, the design file is exported into a format that the laser cutting machine can recognize, such as DXF, AI, or PLT.

Source: Pinterest

Step 2: Prepare and Position the Materials

The next step in laser cutting jewelry is selecting the materials based on design needs and preparing the materials by wiping and removing any dust or debris on their surface. Then, the materials are positioned for cutting according to the thickness and shape of the jewelry.

Step 3: Laser Cutting

At this stage, the design file is imported into the laser cutting machine. This is where the laser power, speed, and frequency parameters are adjusted. The laser cutting machine is started and it uses a high-energy laser beam to precisely control the cutting positions and shapes, moving along the set path to cut the material.

Step 4: Post-Processing

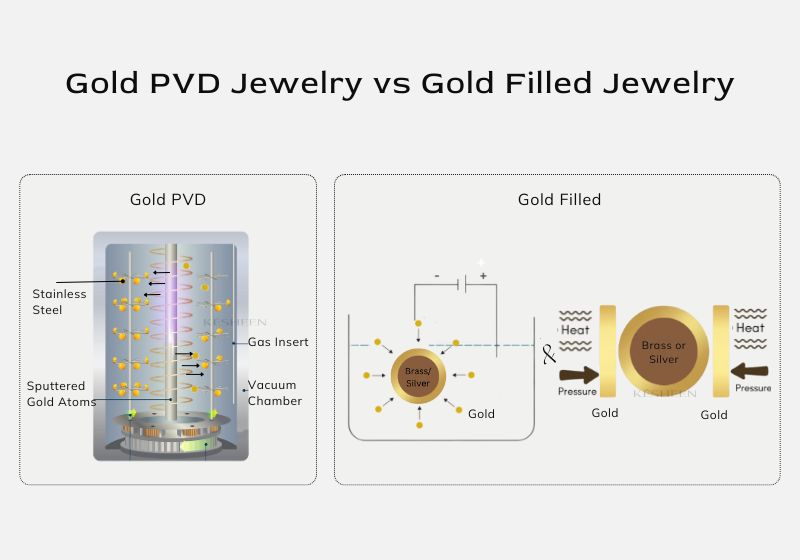

After cutting, the jewelry undergoes initial polishing to remove any burrs or uneven areas caused by the cutting process. Subsequent steps such as PVD coating or stone setting may be performed to enhance the appearance and durability of the jewelry. Some secondary pieces like hooks, strings, or chains can be added to jewelry pieces.

Advantages of Laser Cutting for Jewelry Manufacturing

Laser cutting systems are excellent for jewelry-cutting applications, as they can cut materials of varying thicknesses and ensure high repeatability and speed. Other advantages of jewelry laser cutting include:

Precision and Accuracy

Laser cutters offer a high-accuracy cutting solution for various types of jewelry materials, including metals and non-metals. Their focused laser beam allows for extremely precise cuts, making them suitable for simple and complex designs. As they are guided by computer systems, these machines conveniently make desired jewelry shapes and engravings.

Fast Production and High Efficiency

Laser cutting machines offer high power and speed, much faster than traditional techniques. They cut through materials quickly and process detailed designs rapidly, resulting in the production of large quantities of jewelry pieces within short periods. Due to their automation, these high-end jewelry machines encourage consistency and increase production efficiency.

Minimal Material Waste

Unlike traditional techniques, laser cutters do not require heating of the entire workpiece. Laser cutting machines use highly precise laser beams that focus heat on the specific area to be cut or engraved, minimizing the amount of material wasted during the cutting process. This contactless approach means there’s a reduced risk of material damage.

Flexibility and Customization Capabilities

Laser cutting machines allow you to make innovative and creative jewelry. Aided by computer programs, such as Adobe Illustrator, CorelDraw, AutoCAD, or Fusion360, laser cutters provide cut flexibility for producing simple and relatively complex custom designs. These machines are versatile and flexible as they are capable of processing a wide array of materials, including metals, plastics, wood, etc.

Cost Effective

The precise cutting and engraving of laser cutters ensures materials are utilized efficiently, resulting in decreased waste. This decreases the cost of production, especially when working with expensive materials. As a result of their accuracy, laser cutting machines also save money, time, and effort on the finishing process.

Laser Cutting vs CNC Machining in Jewelry Production

When comparing CNC vs laser cutting machines in jewelry production, they are both used to create designs with great precision. However, they differ in the following areas:

Processing Method

Laser Cutting: Laser cutting machines use a highly focused laser beam to burn and melt the materials. These machines do not rely on physical contact; the laser beam does all the work.

CNC Machining: CNC machines physically touch and carve into the material. They follow an automated set of commands that move the cutting tool to carve out 3D designs and handle thick materials.

Precision and Accuracy

Laser Cutting: Laser cutters are extremely precise, especially for thin materials. They produce smooth, clean edges with minimal burning, making them ideal for carving fine details into jewelry.

CNC Machining: CNC machines have high precision and are better suited for intricate carving and shaping of 3D jewelry.

Application Capabilities

Laser Cutting: Laser cutters have fewer applications for jewelry, mainly used in creating and cutting jewelry designs, patterns and shapes, and laser engraving logos.

CNC Machining: Applications of CNC machining in jewelry making are wide-ranging, including creating molds, prototyping, 3D printing, engraving, stone, and prongs setting.

How Different Manufacturing Techniques Affect Production and Lead Time for Your Pieces?

There are two main manufacturing techniques for stainless steel jewelry. These are casting and cutting techniques. Jewelry manufacturers choose the appropriate technique based on your desired design.

Casting for Complex & Intricate Design

The casting technique is suitable for creating complex and intricate designs. This process involves several steps, including pattern making, lost wax casting, and melting and pouring. Due to the complex and time-consuming processes, it typically results in a longer production cycle, which generally takes 6-8 weeks.

Alternatively, the powder metallurgy technique is used to create intricate designs and shapes. This method creates designs that are more intricate and exquisite. It is also faster for making small batches of complex parts.

Cutting for Hollowing Out Features

The cutting technique is appropriate for cutting simple designs with hollowing-out features. Using this technique, various types of earrings, pendants, and bracelets can be cut into various shapes, patterns, and sizes with hollow features. The cutting process is relatively simple and fast, with a production cycle of 5-6 weeks.

Key Takeaway

Laser cutting jewelry is a versatile, precise, and sustainable technique. Using this method, jewelry designers can create and cut intricate patterns, create hollowing-out feature designs, and add clean engravings to pieces. Due to its advanced technology, a laser cutting machine helps designers save costs, minimize material wastage, boost productivity, and create innovative pieces.