PVD plating and anodizing are two commonly used methods for improving the endurance and appearance of metal surfaces. From producing vivid colors to enhancing corrosion resistance, both techniques have special benefits that apply them extensively in sectors like jewelry and industry.

What is PVD Plating?

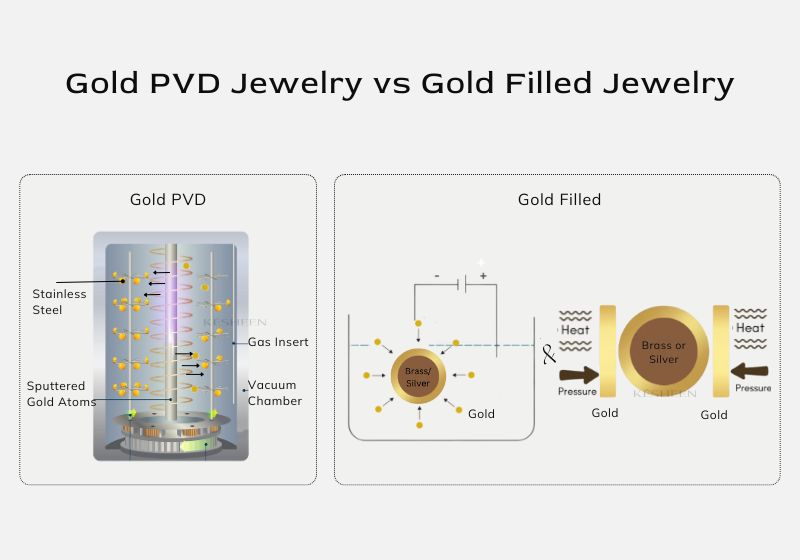

Physical vapor deposition (PVD) is a modern method of applying a durable and ornamental coating on metal surfaces. The metal is placed within a vacuum chamber, where all the air is eliminated to provide a regulated atmosphere. The metal then becomes negatively charged, drawing the coating material, which vaporizes into microscopic particles. These particles stick to the metal to create a thin but robust covering that improves the look and operation of the object.

PVD gold coating jewelry has become well-known mostly because of its capacity to create vivid and long-lasting finishes. PVD has various plating colors such as gold, black, rose gold, and even rainbow-like tones. These coatings look fantastic and increase the metal’s resistance to corrosion and wear, extending its lifetime. PVD plating is a go-to choice for sectors including jewelry, watches, and luxury consumer items because of its mix of looks and uses.

PVD coating has several advantages beyond appearance. The PVD process removes contaminants from ion plated stainless steel jewelry, producing high-purity items safer for wear and less likely to tarnish. Its capacity to provide exact, premium coatings makes it a cost-effective and practical mass production technique free from quality compromise.

This method is not only flexible but also quite sustainable compared to conventional coating methods. It creates longer coatings, uses less raw materials, and generates little waste, lowering the need for regular replacements.

What is Anodizing?

Anodizing is an electrochemical technique whereby an anodic oxide layer forms to improve a metal’s surface, increasing its durability and attractiveness. Usually aluminum or titanium, this technique entails dipping the metal into a chemical bath and running an electrical current. This regulated reaction microscopically changes the surface of the metal, embedding a protective layer right into the substance. Anodizing combines the oxide layer with the metal itself, unlike coatings on top of the surface, greatly resisting corrosion, wear, and environmental degradation.

The capacity of anodizing to produce vivid and distinctive colors is one of its strongest advantages. Depending on the technique and dyes applied, anodizing can produce colors ranging from subdued pastels to brilliant, iridescent hues. These hues are part of the metal’s structure rather than just surface-level; this guarantees long-lasting finishes resistant to fading and chipping. For sectors such as aerospace, automotive, and jewelry where both appearance and durability are crucial, anodized metal is especially appealing.

Anodizing increases the metal’s usefulness in addition to its cosmetic appeal. The oxide layer increases the surface’s hardness, improving its scratch resistance and suitability for daily wear and tear. While anodized titanium is favored in body jewelry for its biocompatibility and corrosion resistance, anodized aluminum, for example, is extensively used in construction and electronics for its lightweight yet durable qualities.

Unlike other surface treatments, Anodization generates little waste and thus avoids the use of dangerous chemicals. Anodizing is a useful method in many different sectors, especially for uses requiring both performance and visual appeal of its combination of durability, and aesthetic adaptability. This procedure is now very essential for producing robust, high-quality, colorful goods.

Main Comparison between PVD and Anodizing

PVD plating and anodizing have different strengths, weaknesses, and optimal uses. This section goes through the differences between the two processes:

Material base

PVD plating can be applied to various metals, including stainless steel and titanium, making it versatile. On the other hand, anodizing is specifically designed for metals like aluminum and titanium. While PVD can work across multiple material bases (especially on stainless steel jewelry), anodizing is limited but provides a unique benefit by altering the surface layer of the metal itself while not changing the base metal’s characteristics.

Effect & Color Retention

While keeping a beautiful and protective covering, PVD plating presents vivid and varied color choices ranging from gold and black to rainbow hues. PVD on stainless steel jewelry offers exceptional durability, retaining its color for at least 2 years. Using the anodic oxide layer, anodizing immediately incorporates the color into the metal, increasing its durability and color retention.

Cost and Price

Jewelers and other industries find PVD plating more reasonably priced as a faster and simpler method. With large-scale production in mind, the method’s efficiency and capacity to coat several metals with little effort help to save manufacturing costs. Jewelry makers that try to mix cost and quality usually choose this affordability. Conversely, anodizing is a more difficult and time-consuming, increasing its general cost. Greater accuracy and effort are needed in the complex electrochemical reaction and the particular dyes employed to get vivid hues.

Anodizing becomes even more expensive for bigger areas or more complex patterns. Many select anodizing for its great durability and color retention, making the investment valuable for industrial uses or high-end, utilitarian jewelry even with its greater cost. Ultimately, deciding between PVD plating and anodizing usually boils to project-specific durability, aesthetic objectives, and financial restraints.

Safety

PVD plating and anodizing are considered safe for many applications, including jewelry.

For people with sensitive skin or allergies, PVD plated food grade stainless steel is thus the recommended alternative.

Sustainability

PVD plating is more environmentally friendly since it does not create hazardous waste or use dangerous chemicals. The procedure consumes less energy and uses fewer harmful components for the surroundings.

Applications

Thanks for its adaptability and range of finishes, PVD plating is used for ornamental and aesthetic uses like jewelry, watches, and other consumer items. Industries including the aerospace, automotive, and medical sectors, where longevity and corrosion resistance are vital, often employ anodizing extensively. While PVD plating is generally used for its wider design options, anodized titanium is popular for jewelry because of its biocompatibility and vivid but robust hues.

Which is Better for the Jewelry Industry?

For jewelers, deciding on PVD plating or anodizing affects cost, safety, durability, and design freedom. Both techniques have special advantages that qualify them for diverse uses in the jewelry business. Here is a thorough comparison to guide jewelers toward the best fit for their requirements.

Price

PVD jewelry is usually the most reasonably priced solution for jewelers because of its quick application technique and capacity to coat many metals effectively. It is particularly well-liked among makers of stainless steel jewelry who want to create reasonably priced, premium items. Though efficient, anodizing is more costly due to its time-consuming and sophisticated technique. For jewelers who concentrate on reasonably priced or mass-produced designs, PVD is feasible for their business.

Safety

Anodized titanium ensures safety for jewelry requiring biocompatibility, like body piercings. Piercing businesses favor stainless steel jewelry manufacturers for their hypoallergenic surgical-grade pieces. The anodizing process accentuates titanium’s inherent hypoallergenic properties, making it suitable for delicate skin and extended usage. Although PVD jewelry is likewise considered safe for regular wear, its covering may flake or peel with time, revealing the underlying metal. This might cause allergic responses or skin irritation, particularly in sensitive skin.

Durability

Since the technique physically combines the color and protective layer into the metal, anodizing is well-known for its great durability and color retention. Anodization actually enhances the base metal with the added protective layer. Although PVD plating provides great resistance against wear and corrosion, its surface-level coating is more likely to be damaged after long usage. Thanks to their process, anodized pieces are suitable for wearable accessories and body piercings.

Flexibility

With its great choice of vivid finishes, gold, rose gold, black, and even rainbow tones, PVD plating shines in terms of adaptability. It’s also a flexible option for fashion-forward and ornamental jewelry designs, as it lets one create complex and artistic patterns. While limited in the spectrum of colors and suitable metals, anodizing produces distinctive finishes like iridescent or pastel hues. For jewelers looking to tap into a wide range of niches or attract different kinds of customers, PVD plated pieces are the better option.

For jewelers who prioritize creative freedom, affordability, and aesthetics, PVD jewelry is the preferable option. Anodizing is better for body jewelry or luxury designs, where durability and safety come first.

Conclusion

PVD plating and anodizing are great methods for improving metal surfaces; each has special advantages catered to distinct uses. PVD plating is appropriate for jewelers wishing to produce colorful patterns with abundant colors and finishes. Conversely, anodizing is recommended for functional or body jewelry, as it is perfect for uses needing great durability, corrosion resistance, and biocompatibility.