There are four major reasons for plating or coating jewelry pieces, which includes to change the color of the jewelry, to add value to the jewelry using a more expensive metal layer, to prevent the jewelry from corrosion, and to cover soldering seams or other related flaws.

Two popular methods that can be used to achieve these purposes are electroplating and PVD plating. In this guide, we will explain these two methods, how different they are to each other, and which is better for stainless steel.

What is Electroplating Jewelry?

This is a popular method of depositing a thin layer of metal (usually brass, gold, silver, or alloy) onto the surface of a jewelry. It involves immersing the jewelry into a solution containing metal ions, which is then charged with an electric current. This transfers the metal ions to the jewelry, thereby forming a thin coating on the jewelry surface.

Electroplating Process

Electroplating entails a process called “electrolysis.” In this process, the substrate (the jewelry to be plated) is dipped into a metal ions solution. An electrical current is passed through the metal ions, which leads to bonding the metal ions to the substrate. This results in a thin, durable coating.

What is Gold Electroplated Jewelry?

This is simply the deposition of a thin layer of gold onto a jewelry surface. Electroplated gold jewelry is usually done to create a jewelry piece that’s durable and has a gold-like effect.

What is PVD Coating on Jewelry?

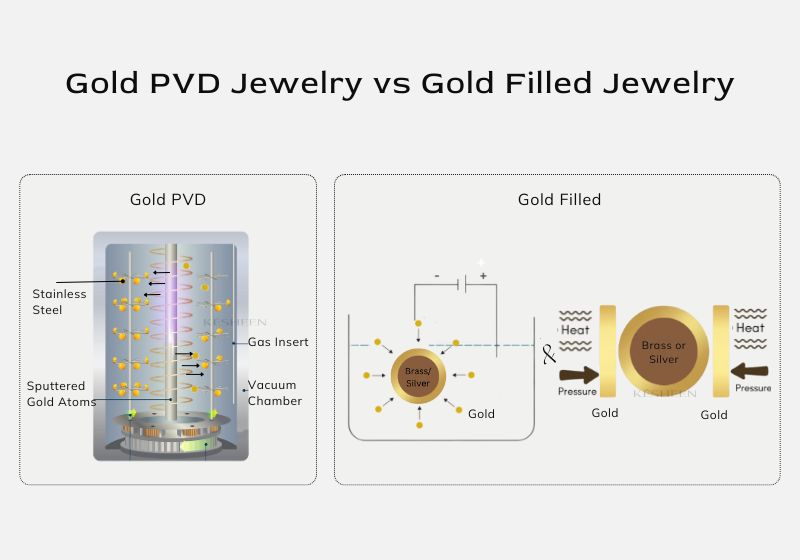

PVD (Physical Vapor Deposition) coating is an advanced method of applying a thin layer of metal particles on a jewelry surface. It involves using a vacuum chamber to vaporize the jewelry so that the coating metal particles will bond tightly on the jewelry’ surface.

Jewelry PVD Coating Process

PVD whole coating process involves cleaning the substrate (the jewelry to be coated) and inserting it into a sealed vacuum chamber to prevent interference from air molecules. Then, the coating metal (usually titanium, zirconium, or chromium) is placed inside the chamber, where it is heated to gas state before bonding firmly on the jewelry’s surface.

PVD Coating vs. Electroplating: Which is better for Stainless Steel Jewelry?

To be straightforward, physical vapor deposition jewelry is often better than electroplated jewelry, especially for stainless steel pieces. Here’s a detailed comparison:

Durability

PVD coating involves a process that creates a bond at the molecular level, making the metal particles adhere tightly. This results in a harder and more resilient jewelry surface. In addition, PVD coating jewelry includes a TiN layer (titanium nitride), which creates a protective barrier on stainless steel pieces, thereby extending their lifespan and reducing frictions, wear, or tear.

Electroplating, on the other hand, produces a thin coating that’s applied merely on the jewelry surface. Stainless steel metal is a hard metal, making electroplating hard to adhere firmly. Thus, electroplating on stainless steel jewelry are prone to wear and tear over time, especially if they are exposed to moisture, chemicals, or friction. This difference is also clear when comparing ion plated vs PVD plated jewelry and PVD plating vs anodizing.

Coating Thickness

PVD coatings on jewelry typically range from 0.03 to 0.08 microns, while the coating thickness of electroplating can be higher. However, this PVD thickness is sufficient for stainless steel and fashion jewelry, providing excellent durability without compromising appearance or performance. In fact, overly thick PVD coatings may lead to adhesion issues and increase the risk of peeling or flaking.

Color

Due to its large-scale, machine-operated process, PVD plating offers limited color flexibility. In contrast, each plating bath of electroplating is simpler to operate and has lower operating costs, allowing for color adjustments.

Environmental Impact

Both PVD and electroplating can be environmentally safe when performed under standardized procedures. However, electroplating requires an additional step for wastewater treatment, making the process slightly more complex than PVD.

Cost

PVD coating is generally more cost-effective than electroplating, especially for stainless steel jewelry. It also offers superior durability, making it a more economical and long-lasting solution for high-volume production.

Here is a comparison table of PVD Coating and Electroplating:

| Features | PVD Coating | Electroplating |

| Process | A vacuum coating process that involves applying a thin layer of metallic particles onto the jewelry surface | Using an electric current to deposit metal ions onto a conductive surface |

| Durability | With a durable TiN layer, offering superior resistance to wear and corrosion | Can’t adhere firmly on stainless steel, prone to wear and tear |

| Coating Thickness | Generally 0.03-0.08 microns, coating adheres firmly to the base metal | The thickness varies and can be higher |

| Color | Limited color flexibility | Allowing color adjustments |

| Cost and Efficiency | Cheaper, especially for mass production | Expensive than PVD coating |

| Environment Impact | Environmentally friendly, no waste water generated | Environmentally friendly, requiring an additional step for wastewater treatment |

Why Electroplating on Stainless Steel Jewelry is More Prone to Wear Off?

Electroplating is a low-energy electrical process. The metal ions arrive at the jewelry with relatively low energy, thereby depositing on the surface softly. Hence, why the plated layer on the jewelry surface wears off and tarnishes quickly.

While this method may be suitable for brass or silver jewelry, stainless steel jewelry is hard and highly unyielding, which is why PVD (including a tough and durable layer of Ti-Nitride) works best.

Jewelry Brands That Use PVD Coating for Stainless Steel Jewelry

PVD coating is increasingly favored by jewelry brands for its durability, resistance to tarnishing, and long-lasting color—especially on stainless steel. Here are two well-known brands that effectively use this technique:

- Jaxxon – Specializing in men’s jewelry, Jaxxon uses PVD coating on its stainless steel chains and rings to ensure long-lasting shine and scratch resistance.

- ATOLEA – Known for ocean-inspired designs, ATOLEA applies PVD coating to its waterproof stainless steel jewelry, offering both style and durability for daily wear.

These brands showcase how PVD technology elevates stainless steel jewelry, combining fashion, function, and long-term wearability.

Quick Facts about Gold Plated/PVD Coating Stainless Steel Jewelry

Does Gold Plated Stainless Steel Jewelry Tarnish?

In all honesty, gold plated stainless steel will eventually tarnish, but the hardness and rigidity of the stainless steel base will slow down the tarnishing speed. PVD gold plated jewelry possesses exceptional resistance against tarnishing, thereby extending the jewelry’s lifespan.

Does 18K Gold Plated Stainless Steel Tarnish?

18K gold PVD-plated stainless steel is highly resistant to tarnishing compared to traditional gold plating. Through physical vapor deposition, a layer of 75% pure gold is fused onto the surface at the molecular level, resulting in a strong, long-lasting finish.

How Long Does Stainless Steel Jewelry Last?

It depends on how well the jewelry is maintained. Generally, stainless steel jewelry without coating can last for a lifetime if maintained properly. While gold coating stainless steel jewelry pieces will still tarnish at the end of the day, their longevity is much higher than other metals like gold, silver and brass.

How Long Does Gold Plating/PVD Coating Jewelry Last?

How long gold plated or PVD coated jewelry lasts depends on the quality of the base metal, the thickness of the applied metal, and how often the jewelry is worn. Normally, a professionally designed PVD coated stainless steel jewelry can last for at least 2 years.

Is Gold Plated Stainless Steel Jewelry Waterproof?

Yes, gold plated stainless steel jewelry is waterproof, especially when plated with the PVD technique. This technique creates a robust bond between the metal coating and the stainless steel base, making it highly resistant to water.

Key Takeaway

While electroplated jewelry is also an alternative choice, it’s suitable for silver, brass and gold jewelry. PVD coating is more ideal for stainless steel jewelry, offering exceptional durability and color retention. If you are not sure which suitable for your jewelry project, consult a custom jewelry manufacturer to get some pro tips.