- Home

- Quality Control

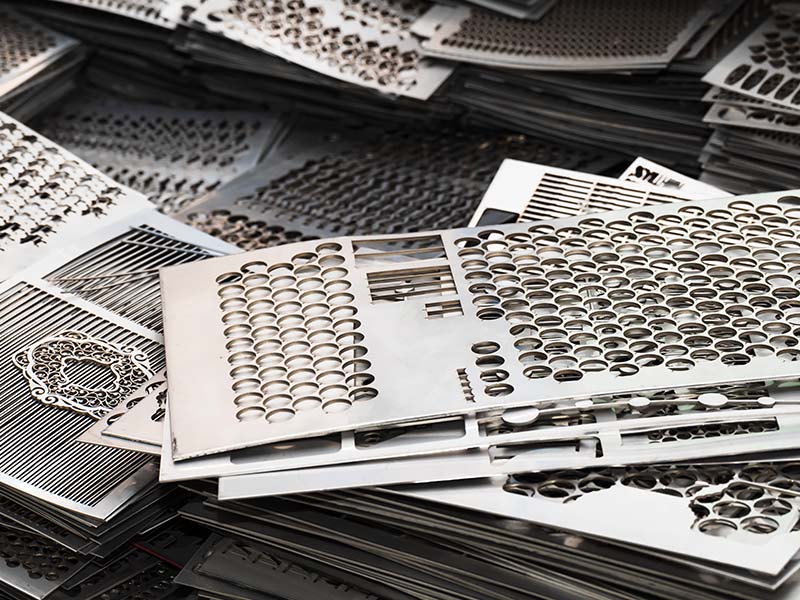

Looking for High Quality Stainless Steel Jewelry? Glad You’re Here.

If you’re looking to offer affordable stainless steel jewelry without compromising on quality, then congratulations, you’ve found the right approach.

Kesheen, as a premium stainless steel jewelry manufacturer, is always guided by a simple philosophy: Create premium stainless steel jewelry that looks great, lasts long, and provides real value without compromise.

Why You Should Opt For Premium Quality Stainless Steel Jewelry?

Quality Fuels Your Business Growth

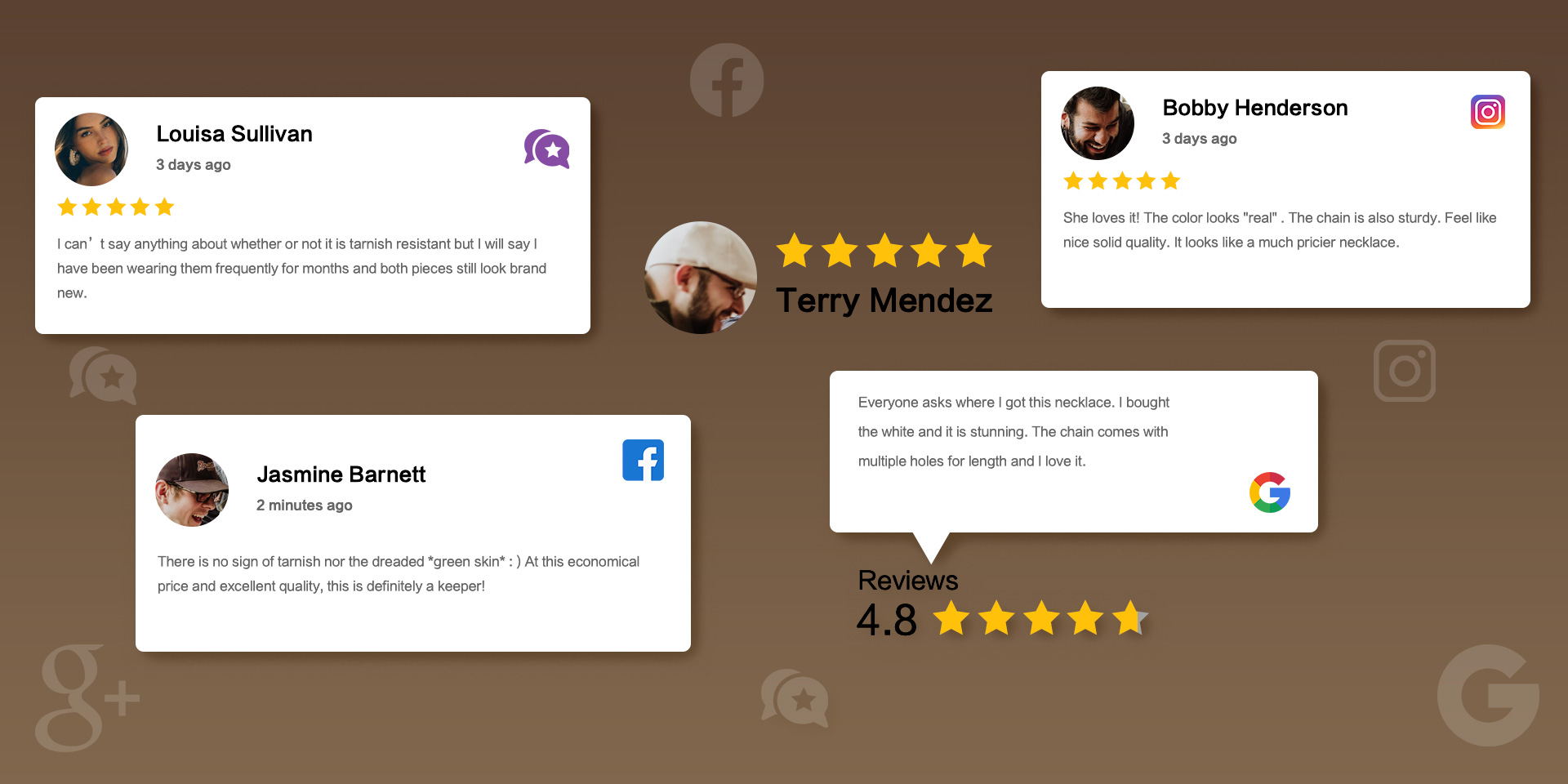

The foundation of any successful jewelry brand is the ability to offer products that stand out—durability, elegance, and long-lasting appeal are all key factors that drive customer satisfaction and repeat business. When you choose quality, you build a strong, reliable brand that customers can trust. This trust translates directly into business growth, as your customers become loyal advocates for your jewelry. Premium products spark excitement, lead to word-of-mouth recommendations, and elevate your brand to a whole new level of credibility.

Quality Builds Loyal Customers and Provides Life-Long Value

Loyalty is born from satisfaction, and satisfaction comes from the confidence that your jewelry won’t tarnish, fade, or break. Premium stainless steel offers resilience, elegance, and hypoallergenic properties, ensuring that your customers enjoy their pieces for years without worrying about quality. By offering timeless pieces that stay beautiful, you’re not just selling jewelry—you’re providing lasting value that your customers will cherish and recommend to others.

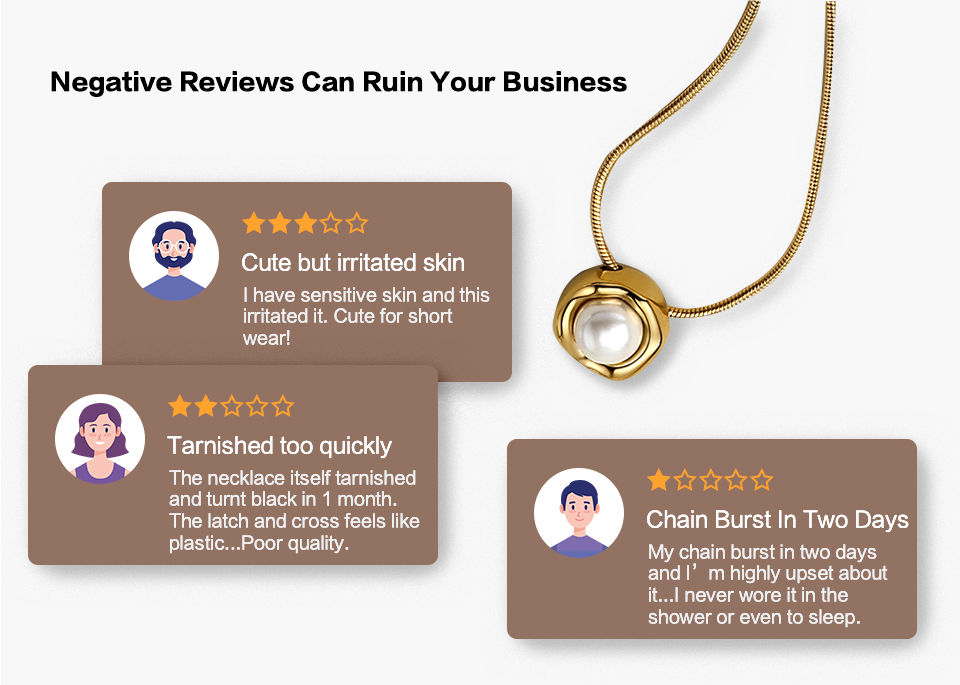

How Kesheen Works For 5-Star Reviews About Quality?

We carefully analyze every negative review to identify the core needs of our customers, which drives our quality management practices. If there are any quality concerns, we work to find effective solutions. Everything we do is aimed at supporting your sustainable business growth.

Core Needs & Expectation Behind

"It looks ‘real’ and expensive than paid."

Customers are paying for more than just jewelry; they’re seeking pieces with a high-end, sophisticated look without the hefty price tag. Offering jewelry that wows them is the best way to earn reviews that highlight ‘Value for money.’ Customers want to feel they’re making a smart, worthwhile investment.

Key quality benchmarks to work on:

- Plating Quality and Thickness

- Surface Treatment

- Surface Perfection

How We Make it Look Expensive?

5-Round High Polishing

We achieve a mirror-like finish with our 5-round high polishing process, ensuring every piece of jewelry gleams with a luxurious shine. This meticulous multi-step process enhances the visual appeal and elevates the overall quality, giving the jewelry a high-end, polished look.

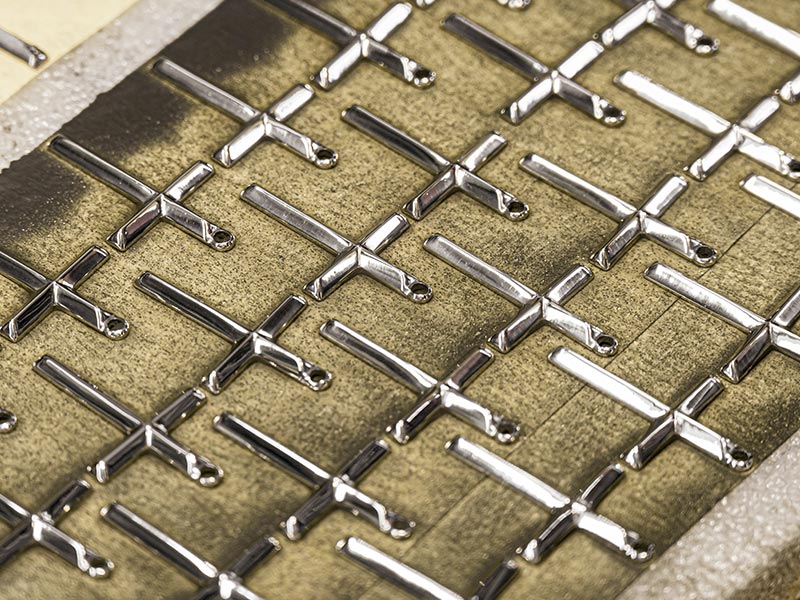

Tailored Manufacturing Techniques

We use specialized manufacturing techniques tailored to each design’s requirements. Whether it’s delicate detailing or heavy-duty durability, our process ensures that each piece achieves the desired balance of strength, beauty, and precision, elevating its value and giving it a high-end appearance.

Unblemished Surface Inspection

Every piece undergoes a thorough surface inspection to detect imperfections such as scratches, dents, or deformations. This extra layer of quality control ensures that your jewelry is free from flaws, giving it a smooth, pristine finish that looks exquisite and expensive.

Premium Stones and Findings

To make each piece truly stand out, we source only premium stones and high-quality findings. Whether it’s sparkling diamonds, vibrant gemstones, or high-grade metal components, these carefully selected materials elevate the overall design, giving your jewelry that luxurious, high-end appeal.

Core Needs & Expectation Behind

"It doesn't irritated my sensitive skin."

Customers are looking for jewelry that’s both stylish and comfortable. If your pieces are gentle on the skin, without causing irritation, they’re more likely to become go-to items for sensitive skin wearers. Jewelry that’s kind to the skin is essential for building long-term wearability, especially for those with sensitivities or allergies. Customers want to feel confident wearing your jewelry without worrying about discomfort.

Key quality benchmarks to work on:

- Hypoallergenic metal and materials

- Lead and Nickle Content

- Smooth Surface Treatments

How We Make it Hypoallergenic?

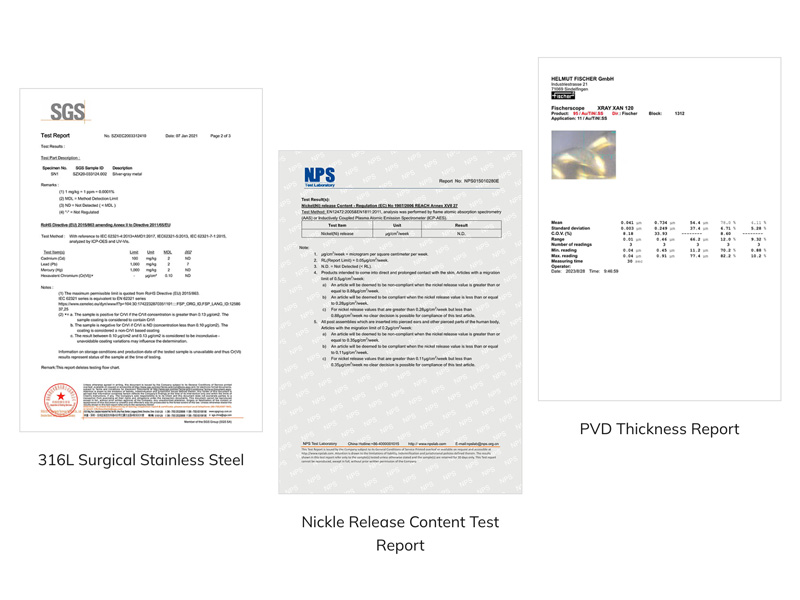

Meeting Nickel Content Standards

We prioritize your safety by ensuring all of our jewelry complies with strict nickel content release regulations, including REACH (EU) and California Proposition 65 (USA). This means our jewelry is free from harmful nickel levels, making it a safe and hypoallergenic choice for those with sensitive skin.

316 Surgical Stainless Steel Available

You have access to 316 surgical stainless steel, a premium, corrosion-resistant material known for its hypoallergenic properties. Ideal for sensitive skin, this high-grade metal minimizes the risk of irritation and ensures lasting comfort without compromising on style or durability.

Core Needs & Expectation Behind

"It's durable and won't break easily."

Customers want jewelry that can keep up with their active lifestyle—pieces that are sturdy, reliable, and made to last. A high level of durability is essential to ensuring your jewelry withstands daily wear and tear without breaking, bending, or losing its shape. When customers feel that your jewelry can handle the demands of everyday use, they are more likely to view it as a smart, long-term investment.

Key quality benchmarks to work on:

- Strength of Materials

- Reinforced Construction

- Testing for Resilience

How We Make it Sturdy and Solid?

Welded Jump Ring

We use welded jump rings in our jewelry to create strong, secure connections. This method ensures that links stay intact, preventing breakage or separation over time. With welded joints, your jewelry remains solid and reliable, even through everyday wear and tear.

500 Times Open & Close Test

To ensure the highest level of durability, each piece undergoes a 500 times open and close test. This rigorous testing simulates real-world usage and ensures that clasps, fasteners, and connections hold up without compromising on functionality, giving your jewelry long-lasting reliability.

Tensile Test

We perform 30N tensile tests on our jewelry to measure its resistance to stretching and breaking under pressure. This ensures that every piece is built to endure without losing its shape or structure, providing you with solid, dependable jewelry that lasts for years.

Core Needs & Expectation Behind

"They don't tarnish even if I shower with them."

One of the biggest concerns with jewelry is tarnishing, especially when exposed to moisture. Customers want to know that their jewelry will retain its beautiful finish even after exposure to water, sweat, or daily activities like showering. Jewelry that doesn’t tarnish offers both aesthetic longevity and peace of mind, making it a popular choice for those who want low-maintenance, reliable pieces.

Key quality benchmarks to work on:

- Corrosion Resistance

- Wear Resistance

- High-Quality Plating

How We Make it Tarnish-Free?

Plating Content and Thickness

We strictly control the plating process by using real gold and ensuring a plating thickness of 0.03–0.08μm for PVD coating. This ensures a smooth, even finish that resists tarnishing and holds up beautifully against daily wear.

Abrasion Test

Each piece is tested using specialized equipment that simulates rubbing and friction. This process confirms that the plating won’t fade or peel, even after extended use or contact with skin and clothing.

Artificial Sweat Test

To simulate real-world conditions, we conduct a sweat test using artificial perspiration. This helps verify that our jewelry maintains its color and shine even when exposed to moisture, heat, and daily activities like showering or working out.

Core Needs & Expectation Behind

"The stones arrived intact. Didn't fall out."

Customers want to be assured that their jewelry, especially pieces adorned with stones, is securely crafted to withstand handling and delivery. When stones are set properly, they stay in place, adding to the overall durability and value of the piece. A customer’s peace of mind is essential, as they expect their jewelry to arrive in perfect condition and remain that way over time.

Key quality benchmarks to work on:

- Secure Stone Setting

- Testing for Stone Stability

- Packaging for Protection

How We Make it Secure?

Secure Setting and Smooth Edges

ach stone is securely held in place with precisely set prongs, ensuring that the stone won’t shift or fall out. We also ensure that the edges are smooth with no voids, creating a flawless, tight fit that guarantees the stone remains stable and secure throughout its lifespan.

3M Tape Test

To ensure the utmost security, we perform a 3M tape test—a rigorous test where the stone won’t shift or come loose, even when strong adhesive tape is applied. This test ensures that our stones stay firmly set and secure, no matter how the piece is handled.

Protetive Packaging

Our custom packaging ensures that each piece, especially those with delicate stones, arrives safe, secure, and in perfect condition, so you can be confident that your stones are protected every step of the way.

Precision Crafted

Our Quality Control Checklists for All Jewelry Types

At Kesheen, we believe that quality is the foundation of every piece of jewelry we create. Our comprehensive quality checklists ensure that every product undergoes a strict inspection process. From selecting premium materials to the final polish, we check every detail to guarantee that every piece exceeds industry standards and provides lasting value to our customers.

| Reliability Test Items* Material- Special attachment | Vibration Test | Abrasion Test | Artificial Sweat Test | Drop Test | Temperature Humidity Circle | Adhesion (3M Tape Test) | UV Test | Pulling Test | Salt Spray Test | Appearance Inspection | Structure Inspection |

|---|---|---|---|---|---|---|---|---|---|---|---|

| * Stainless Steel Without Plating | ❌ | ❌ | ❌ | ❌ | ❌ | ❌ | ❌ | ❌ | ❌ | ☑️ | ☑️ |

| * Stainless Steel With Plating | ❌ | ☑️ | ☑️ | ❌ | ❌ | ☑️ | ❌ | ❌ | ☑️ | ☑️ | ☑️ |

| * Stainless Steel With Enamel, Spray, or Painting | ❌ | ☑️ | ☑️ | ❌ | ☑️ | ☑️ | ❌ | ❌ | ☑️ | ☑️ | ☑️ |

| - With Pendants/Components | ☑️ | ❌ | ❌ | ☑️ | ❌ | ❌ | ❌ | ❌ | ❌ | ☑️ | ☑️ |

| - With Pearl/Stone Adhesion | ☑️ | ❌ | ❌ | ☑️ | ❌ | ❌ | ❌ | ❌ | ❌ | ☑️ | ☑️ |

| - With Plate/MOP Adhesion | ☑️ | ❌ | ❌ | ☑️ | ❌ | ❌ | ❌ | ❌ | ❌ | ☑️ | ☑️ |

| Reliability Test Items* Material- Special attachment | Vibration Test | Abrasion Test | Artificial Sweat Test | Drop Test | Temperature Humidity Circle | Adhesion (3M Tape Test) | UV Test | Pulling Test | Salt Spray Test | Appearance Inspection | Structure Inspection |

|---|---|---|---|---|---|---|---|---|---|---|---|

| * Stainless Steel Without Plating | ❌ | ❌ | ❌ | ❌ | ❌ | ❌ | ❌ | ❌ | ❌ | ☑️ | ☑️ |

| * Stainless Steel With Plating | ❌ | ☑️ | ☑️ | ❌ | ❌ | ☑️ | ❌ | ❌ | ☑️ | ☑️ | ☑️ |

| * Stainless Steel With Enamel, Spray, or Painting | ❌ | ❌ | ☑️ | ❌ | ☑️ | ❌ | ☑️ | ❌ | ☑️ | ☑️ | ☑️ |

| - With Pendants/Components | ☑️ | ❌ | ❌ | ☑️ | ❌ | ❌ | ❌ | ❌ | ❌ | ☑️ | ☑️ |

| - With Pearl/Stone Adhesion | ☑️ | ❌ | ❌ | ☑️ | ☑️ | ❌ | ❌ | ❌ | ❌ | ☑️ | ☑️ |

| - With Plate/MOP Adhesion | ☑️ | ❌ | ❌ | ☑️ | ☑️ | ❌ | ❌ | ❌ | ❌ | ☑️ | ☑️ |

| Reliability Test Items* Material- Special attachment | Vibration Test | Abrasion Test | Artificial Sweat Test | Drop Test | Temperature Humidity Circle | Adhesion (3M Tape Test) | UV Test | Pulling Test | Salt Spray Test | Appearance Inspection | Structure Inspection |

|---|---|---|---|---|---|---|---|---|---|---|---|

| * Stainless Steel Without Plating | ❌ | ❌ | ❌ | ❌ | ❌ | ❌ | ❌ | ❌ | ❌ | ☑️ | ☑️ |

| * Stainless Steel With Plating | ❌ | ☑️ | ☑️ | ❌ | ❌ | ❌ | ❌ | ☑️ | ☑️ | ☑️ | ☑️ |

| * Stainless Steel With Enamel, Spray, or Painting | ❌ | ❌ | ☑️ | ❌ | ☑️ | ❌ | ☑️ | ❌ | ☑️ | ☑️ | ☑️ |

| - With Pendants/Components | ☑️ | ❌ | ❌ | ☑️ | ❌ | ❌ | ❌ | ☑️ | ❌ | ☑️ | ☑️ |

| - With Pearl/Stone Adhesion | ☑️ | ❌ | ❌ | ☑️ | ☑️ | ❌ | ❌ | ☑️ | ❌ | ☑️ | ☑️ |

| - With Plate/MOP Adhesion | ☑️ | ❌ | ❌ | ☑️ | ☑️ | ❌ | ❌ | ☑️ | ❌ | ☑️ | ☑️ |

| Reliability Test Items* Material- Special attachment | Vibration Test | Abrasion Test | Artificial Sweat Test | Drop Test | Temperature Humidity Circle | Adhesion (3M Tape Test) | UV Test | Pulling Test | Salt Spray Test | Appearance Inspection | Structure Inspection |

|---|---|---|---|---|---|---|---|---|---|---|---|

| * Stainless Steel Without Plating | ❌ | ❌ | ❌ | ❌ | ❌ | ❌ | ❌ | ☑️ | ❌ | ☑️ | ☑️ |

| * Stainless Steel With Plating | ❌ | ☑️ | ☑️ | ❌ | ❌ | ❌ | ❌ | ☑️ | ☑️ | ☑️ | ☑️ |

| * Stainless Steel With Enamel, Spray, or Painting | ❌ | ☑️ | ☑️ | ❌ | ☑️ | ❌ | ☑️ | ☑️ | ☑️ | ☑️ | ☑️ |

| - With Pendants/Components | ☑️ | ❌ | ❌ | ☑️ | ❌ | ❌ | ❌ | ☑️ | ❌ | ☑️ | ☑️ |

| - With Pearl/Stone Adhesion | ☑️ | ❌ | ❌ | ☑️ | ☑️ | ❌ | ❌ | ☑️ | ❌ | ☑️ | ☑️ |

| - With Plate/MOP Adhesion | ☑️ | ❌ | ❌ | ☑️ | ☑️ | ❌ | ❌ | ☑️ | ❌ | ☑️ | ☑️ |

Full-Cycle, Holistic, Seamless Quality Management Approach

1

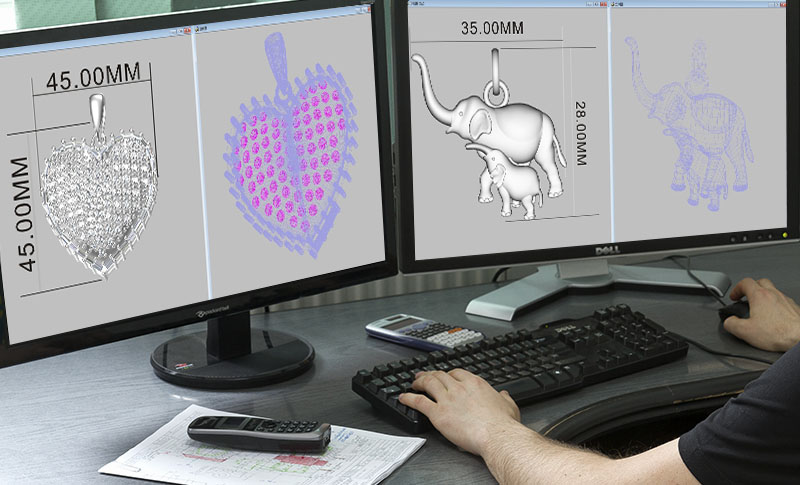

Proof-Free Design Review In The Early Stage

Before we move into production, we carry out a comprehensive design evaluation that ensures your concept is fully aligned with our manufacturing capabilities. This “Proof-Free Design Review” eliminates the need for multiple rounds of proofing, streamlining the process and saving valuable time.

Our specialists carefully assess every aspect of your design—materials, proportions, finishes, and functionality—ensuring it’s ready for seamless transition into production. By catching potential issues early, we avoid delays and make sure that what you envisioned is translated into the final product with precision, without unnecessary revisions.

2

Strict Material Standards for Premium Jewelry

Every time Kesheen sources stainless steel, minerals, packaging materials, and production consumables from a new supplier, we carefully evaluate their ethical practices and certifications.

Before any materials enter the production process, we conducts thorough checks to ensure they meet the required production standards. If a batch does not meet the criteria, it is returned to the supplier for reprocessing or replacement, ensuring that only the highest quality materials are used in the manufacture of stainless steel jewelry.

3

Real-Time Craftsmanship Inspection In Process

At Kesheen, we have specialists overseeing the five key elements in the manufacturing process: craftsmanship, machinery, materials, operations, and the production environment. This ensures that all processes are standardized, while proactively addressing any exceptions.

To maintain efficiency and ensure timely delivery, we take prompt action—whether it’s screening semi-finished jewelry, reworking incomplete pieces, or repairing any defects.

4

In-Person Final Quality Evaluation of Each Piece

To ensure that each piece of stainless steel jewelry maintains its perfect condition before delivery, every item undergoes a final cleaning and inspection process. Any defective pieces are selected for re-inspection and repair, preventing them from being mixed with the rest of the batch.

If you encounter any quality issues after receiving your order, please don’t hesitate to contact us. Our dedicated team will not only resolve the issue but also conduct a thorough analysis to identify the root cause. We then implement long-term improvements, such as mold adjustments, craftsmanship enhancement, and staff training, to ensure consistent quality moving forward.

Hassle-Free Returns & Quality Warranty for Peace of Mind

Our Commitment to Quality – No Compromises

At Kesheen, we see quality issues as an opportunity to show how much we care. If any part of your jewelry doesn't meet the standards you expect, we take it personally. Our approach to quality is all about ownership and responsibility — we’re committed to ensuring that every piece we send out is flawless. If something goes wrong, it’s on us to make it right, no questions asked.

How We Deliver on Our Promise

We stand by every piece of jewelry we produce with a comprehensive warranty that covers any manufacturing defects. Should any issue arise, our easy return process allows you to return or exchange your item without hassle. We’re here to act swiftly, offering replacements or refunds to ensure you’re fully satisfied with your purchase — because your trust and satisfaction are what matter most to us.

Our Clients Speak About Our Quality

“I’ve worked with a lot of jewelry manufacturers over the years, but Kesheen has truly set the bar for quality. From the moment I received my order, I could tell that every piece was crafted with the utmost care and precision. The attention to detail is incredible!”

— Emma R., Jewelry Brand Owner

How can Kesheen help?

Kesheen provides solutions based on your specific requirements. Connect with us today and unlock new possibilities.

- Upgrade the quality of your current design

- Create an exclusive jewelry design with ideas

- Simply look for a factory to bring your design to life

- Source quality stainless steel jewery for your shop