A young Australian jewelry startup had a tennis necklace design made by another manufacturer. While it initially sold well and became their top-selling piece of jewelry, customers started returning the piece and citing poor quality as the main concern. This resulted in a 3% refund rate and roughly 300 items left in inventory, heavily impacting their sales and brand reputation.

Wanting to resolve the quality issue and restore consumer faith in their brand, they sought a reliable jewelry manufacturer and found us online. They asked us to update the tennis necklace’s design and address the quality concerns customers complained about with the piece.

A REAL Challenge Despite Our Decades of Experience

During initial discussions, the client pointed out three main concerns regarding the tennis necklace, mainly:

- Stones falling from the piece,

- Parts break off easily, and

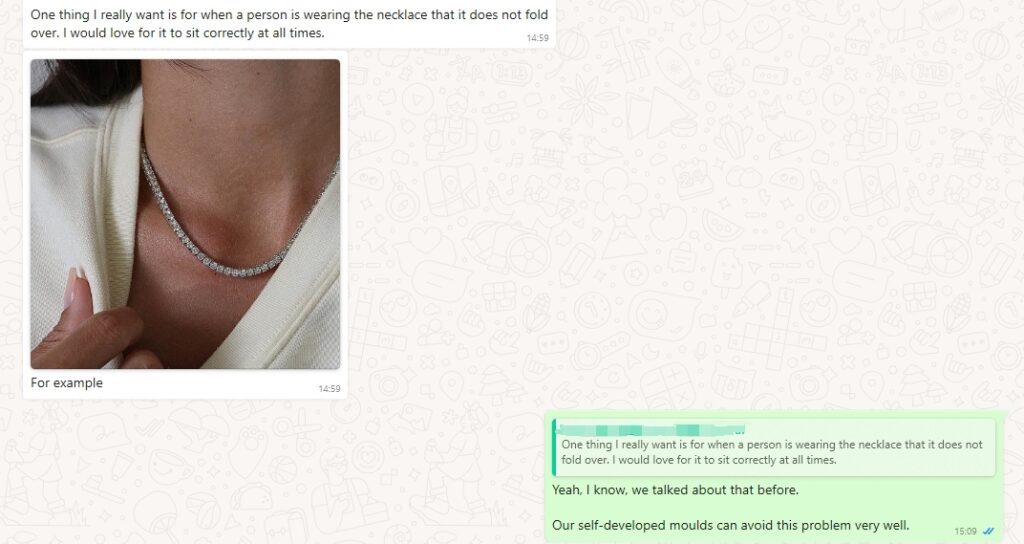

- The bracelet keeps flipping over when worn.

Taking on the task may be challenging for most jewelry manufacturers. But thanks to Kesheen’s years of experience and renowned expertise in jewelry production, we’ve easily figured out how to resolve the issues and create an exceptional tennis necklace.

Most manufacturers typically make wholesale tennis jewelry through lost wax casting using a pre-made mold sourced from the market. Although these rubber molds are cheaper and can shorten production time, they produce low-quality jewelry pieces. Hence, the issues the client’s customers were experiencing with the accessory.

To avoid these problems, we’re attempting an advanced manufacturing technique in creating their tennis bracelets called powder metallurgy. While only a few jewelry makers use this process, we’re confident and skilled enough to ensure the success of this application.

Reasons Why Their Previous Tennis Chains Perform Poorly

By analyzing the quality and production process used in making their previous batch of tennis necklaces, we’ve figured out three reasons leading to the accessory’s poor performance.

Pre-made Mold Bought Directly From the Market

For many pieces of jewelry, the mold serves as the base where the accessory will take its form. As such, the mold’s quality will dictate the overall quality and performance of the final product.

In this situation, the previous manufacturer opted to use a generic, cheaper mold for the project. Due to being poorly made, it didn’t provide enough stability for the tennis necklace to avoid flipping over and breaking.

Not Rigid and Secure Structure

Another pain point we’ve seen with the tennis necklace is a lack of a stable structure. The structure the previous manufacturer used doesn’t suit the piece well, resulting in issues with its overall performance. Part of our plan is to adjust the structure of the piece, making it more rigid and improving its stability.

Poor Quality Stone and Stone Setting Methods

Additionally, our expert designers noticed the stone setting method that was used on the tennis necklace. The old batch had a claw setting to hold the stones in place, which doesn’t work well for stainless steel jewelry applications. This caused the stones to fall off the piece, much to the customers’ dismay.

How Kesheen Does It Better: Keys to High-Quality Tennis Necklaces

After much discussion with the client and careful analysis of their concerns, our expert team drafted the best solution to improve the product and make it more profitable. Leveraging our craftsmanship expertise and years in the jewelry industry, we’ve decided that powder metallurgy is the best path to take for the project.

We presented the solution to the client, explaining how the process would go and the expected results. While the production cost will rise due to this method, we can guarantee a drastic drop in refund rates and boost their brand image. After addressing their questions and giving them assurance on the final tennis necklace, the client agreed, and we started on the project.

Create CAD Design

The initial part of the process involves creating a new CAD design for the tennis necklace. Our design experts took extra time to fine-tune the structural details of the piece during this time, addressing one of the client’s main concerns.

Make The Mold By Ourselves, Using Powder Metallurgy Mold

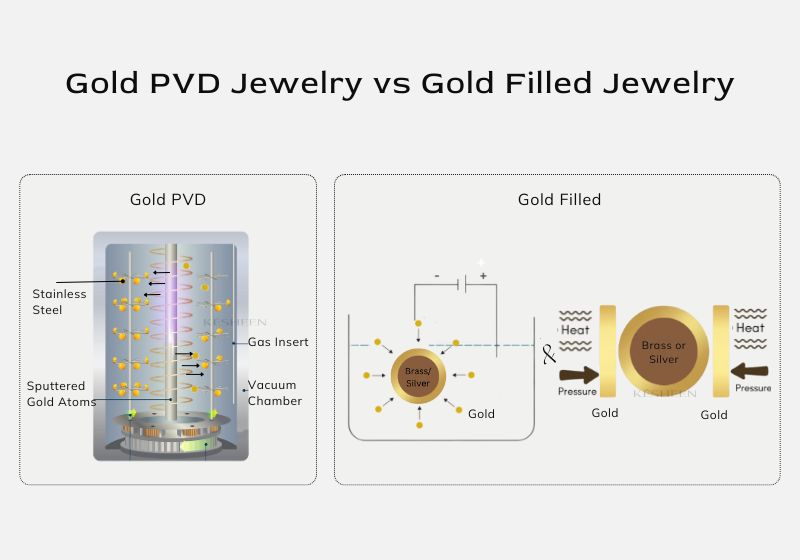

For this project, we chose to create the mold using powder metallurgy rather than the common rubber molding method. In powder metallurgy or PM, we blend and compact metal powders into their intended shape, then heat them below the metal’s melting point, which will bond them tightly.

By opting for the PM method, the tennis necklace will have a more rigid and secure structure, eliminating the issue of the piece flipping over when worn. It will also have exceptional strength and complex designs not found in pre-made molds.

Adjust The Structure With 45 Degrees Between Each Component

In jewelry manufacturing, structure refers to the stability and overall appearance of the accessory, especially when in use. To solve the structural concerns of the tennis necklace, we added a 45° angle between each component.

The inclusion of the 45° angle ensures that the chain and stones would always face up when worn. It also adds another layer of intricacy and detail to the final piece, further enhancing its aesthetic appeal.

Use 3A Cubic Zirconia, Securely Setting the CZ By Hand.

For the stone, we agreed on using 3A cubic zirconia as the main gemstone for the tennis necklace. A popular alternative to diamond, this has a high refractive index compared to other gemstones, giving it a brilliant shine.

Instead of claw setting, we went with the manual hand setting technique in placing the stones on the tennis necklace. Handled by expert craftsmen, the stones are set individually by hand, using high-quality glue to secure them in place. This method ensures that the cubic zirconia won’t fall off even after long days of use.

High Polishing to A Mirror Effect

After crafting the tennis necklace, they go through five rounds of polishing using different methods, each handled by a seasoned craftsman. This helps the jewelry achieve a mirror effect that boosts its overall appearance.

Meticulous Quality Control

As part of Kesheen’s commitment to excellence, every piece undergoes a series of quality inspections after each production step. Our inspectors meticulously check the consistency of the accessory, making sure it meets our standards. This also ensures that the issues identified in the previous batch won’t recur on the new line of tennis necklaces from our warehouse.

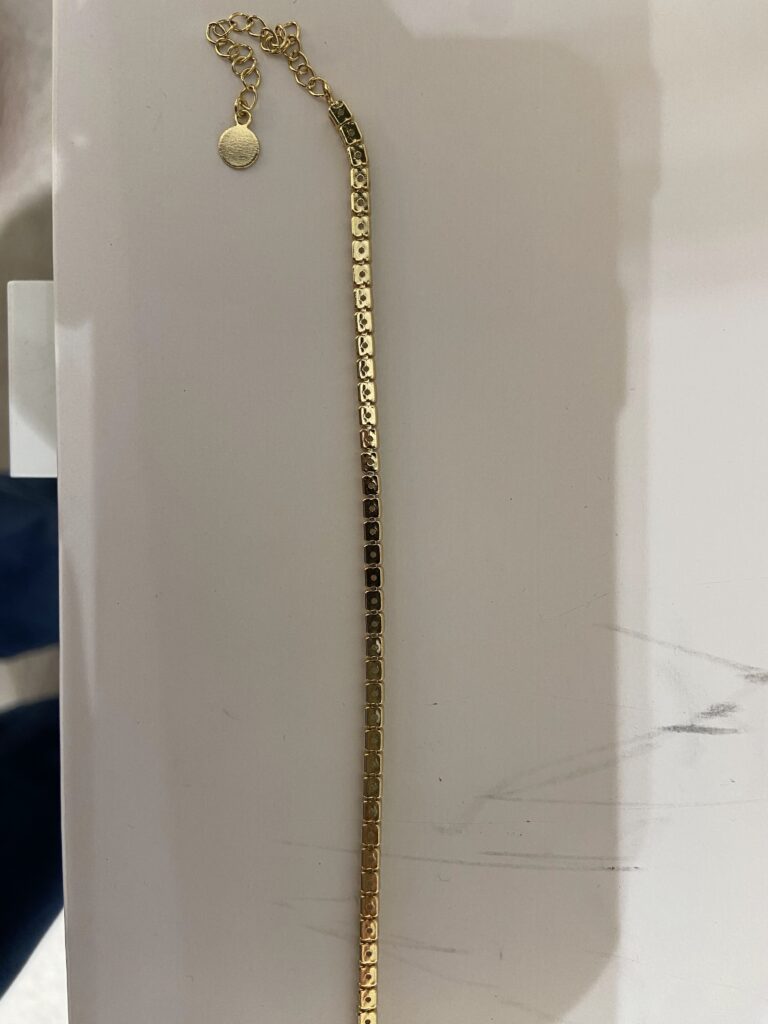

Proven Success

In the end, we were able to create a stunning, high-quality tennis necklace that won’t flip over, break, or have the stones fall while worn. We then sent the client a sample of the finished piece, which they loved immediately. They highlighted the quality and incredible craftsmanship of the jewelry, thanking us for a job well done.

They then added the new tennis necklace to their store, which sold out in a number of days with no refunds in sight. Due to the positive customer response, they expressed desire to work with us again for another jewelry design.

Trusting Kesheen for Your Next Jewelry Project

This project exemplified the expertise and dedication Kesheen has in delivering exceptional custom jewelry. Despite previous issues with their current tennis necklace, we’ve leveraged our years of manufacturing experience and implemented solutions to enhance the final product. While we opted for a higher-cost jewelry production method, the results proved to be worth the price.

Now, we have another satisfied client who wants to work with us again. All in a day’s work for Kesheen.