The process of jewelry making has evolved over the years, moving from techniques like hand fabrication, lost-wax casting, electroforming, and 3D printing to CNC jewelry machining (which is currently making the biggest wave in the jewelry industry).

In this article, we will discuss everything about CNC machining, especially how it improves jewelry production and solves numerous problems faced by former jewelry making processes.

What is CNC Machining for Jewelry Making

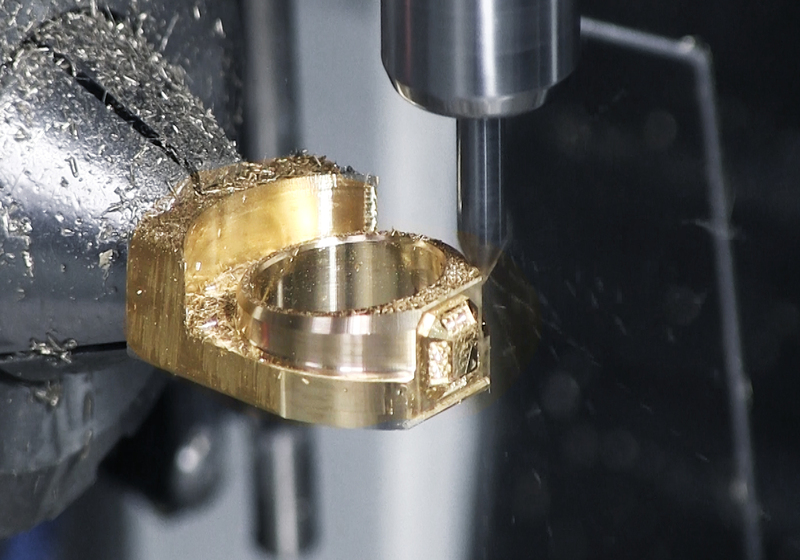

CNC (Computer Numerical Control) machining is a modern prototyping process that uses computer-aided design (CAD) software to create digital replicas of jewelry designs, which are converted into a format that’s understandable by the CNC machine.

Source: Pinterest

The machine follows the instructions pre-programmed by the CAD software to create jewelry pieces with intricate shapes, designs, and patterns.

What Types of Jewelry Can Be Produced by CNC Machining Technique?

The CNC machining technique can be used to produce various types of jewelry. At Kesheen, we produce several custom CNC jewelry for women and men, helping you to expand the range of your business. Some of our refined jewelry CNC pieces are necklaces, rings, earrings, bracelets, pendants, chains, piercing jewelry, etc.

CNC Machining Processes in Jewelry Production

The CNC jewelry production process combines CAD software with CNC milling machines to create intricate pieces. Here’s a quick overview of the main steps involved:

Step 1: Designing

The production process starts with using CAD software to create a 3D design of the jewelry. The design serves as a blueprint for production, guiding the CNC machine on what to do. After creating the design, choose the jewelry material. Common choices are gold, silver, platinum, and titanium.

Step 2: Preparing the CNC Machine

Then, the CNC milling machine is set up and the CAD design file is loaded into the machine, which will be converted into instructions that the CNC machine understands. Ensure the correct cutting tools are installed for excellent production.

Step 3: Milling

With the design and CNC machine in place, the jewelry piece is milled from the selected material. The machine follows the design guide of the CAD file, which precisely carves out the jewelry using rotary cutters to remove materials.

Step 4: Finishing

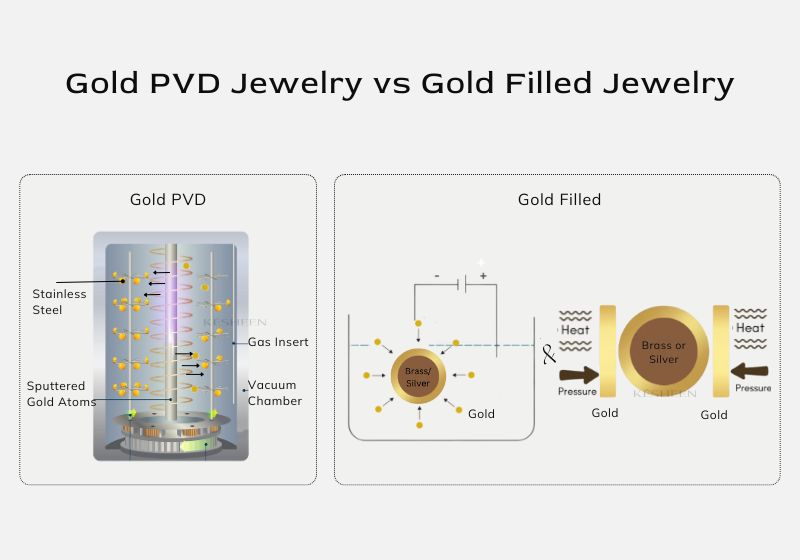

Once milling is completed, the jewelry is cleaned and polished. Any excess material attached to the jewelry is removed and a final inspection is conducted to meet the desired specifications. Some finishing processes like PVD coating, electroplating, or engraving can be applied for additional protection and uniqueness.

Advantages of CNC Machining in Jewelry Manufacturing

Here are the benefits of CNC for jewelry over other methods:

Accuracy and Precision

The CNC manufacturing machine can create intricate shapes, designs, and complex patterns with high precision. The machine keenly follows the CAD instructions, making sure each piece is produced with exact measurement and zero error. This accuracy and precision is very essential for jewelry that requires aligned symmetry, such as rings and earrings, where small mistakes can impact the overall jewelry.

Design Versatility

The CNC machine for jewelry opens up new possibilities for exquisite craftsmanship, allowing designers to express their creativity without any barriers. This machine effortlessly produces complex, multi-dimensional, and intricate designs that will be challenging to achieve with traditional methods like hand fabrication or lost-wax casting.

Material Diversity

CNC machine for jewelry making allows for the manufacturing of a broader range of pieces, such as gold, silver, platinum, stainless steel jewelry, etc. The machine supports different materials, allowing jewelry designers to produce unique and custom pieces while expanding the creative opportunities to mix different materials.

Production Time and Cost Efficiency

CNC jewelry machines are faster and more efficient than other jewelry making methods. It enables mass production, streamlines the production process, significantly reduces production time, and lowers labor costs. This increased efficiency allows for faster turnover time, minimizes errors, and cuts down on waste, making it extremely cost-effective.

High Durability and Excellent Quality

CNC machining produces jewelry pieces that have smooth surfaces, high structural integrity, extremely hard, and offer double the durability of typical cast pieces. CNC jewelry products have high capability to withstand scratches and deformation, making them suitable for everyday wear. This includes engagement rings and bracelets that need to resist daily wear & tear.

Applications of CNC Machining in Jewelry Making

What is a CNC machine used for in jewelry manufacturing? How does it help to achieve different effects? Explained below are the various aspects of jewelry manufacturing where CNC machine can be applied:

Creating Molds for Wax Mold with CNC Machining

A very common method used for making molds in jewelry manufacturing is “wax modeling,” which is time-consuming and prone to human error. But with CNC machining, precise and detailed molds can be created faster without any defect.

Source: Pinterest

CNC mold making produces sturdier molds that can be used multiple times. It allows for accurate and consistent reproduction of complex patterns, reducing the time, cost, and likelihood of defects when creating jewelry pieces.

Creating Master Model with CNC Machining

Metal casting is another commonly used method for creating jewelry. Rather than using metal casting, which involves creating jewelry by hand, CNC improves the production process by using automated technologies.

Source: Pinterest

CNC creates master models, which serve as references for making multiple copies of the design, ensuring consistency and quality in mass production. The precision of CNC machining jewelry enables the production of high-quality models that can be used in both casting and direct prototyping processes.

Creating Intricate Structures

One of the key applications of CNC for jewelry making is creation of intricate structures that may be difficult or impossible to create with other jewelry making processes. CNC is applied in creating complicated and intricate structures, such as complex filigree and geometric designs.

Source: Pinterest

CNC machines efficiently carve detailed patterns, allowing jewelers to push the boundaries of what is possible. As a professional custom jewelry manufacturer, we often use this technique to make various types of pieces, including stainless steel jewelry, where intricate detailing is crucial.

Prototyping and 3D Printing

CNC technology makes rapid prototyping and 3D printing more accessible and efficient. It allows jewelry designers and manufacturers to create samples before production. This helps to test the form and function of the piece before committing to mass production.

Source: Google

CNC for jewelry offers a tangible, high-quality representation of the final piece, enabling you to see and have a feeling of how the jewelry will be after production is completed.

Engraving Jewelry

The CNC machine has made it easier to carve patterns or text on molds and jewelry. It engraves designs and textures on a variety of materials, including precious metals and gemstones, allowing for the production of different jewelry pieces with unparalleled accuracy.

Source: Pinterest

This is particularly useful for personalizing jewelry with names, dates, or decorative designs. CNC for jewelry ensures clean, crisp lines and can handle detailed work on pieces like rings, bracelets, and pendants.

Polishing and Surface Finishing

Jewelry polishing and finishing can be done through CNC machines, ensuring that each piece is smooth and free of imperfections.

Source: Pinterest

While hand polishing and surface finishing can be used, CNC machining provides a clean surface that reduces the amount of post-processing needed. This technique can also be used to apply different textures, ranging from mirror finishes to matte surfaces.

Stones and Prongs Setting

CNC is used to set the position of stones for stainless steel jewelry, because stainless steel metal is too hard for traditional prong setting. Therefore, CNC is needed to precisely carve out the position of stone and prongs.

Source: Pinterest

CNC jewelry stones are set to fit securely, symmetrically, and consistently. Using CNC machining largely minimizes the risk of damaging the stones and prongs during the setting process.

Key Takeaway

CNC has revolutionized the way jewelry is made nowadays. It simplifies the production process, resulting in faster, less expensive, more durable, and more accurate jewelry products.You can contact us to explore the benefits of CNC for jewelry making, and enjoy unique opportunities to bring your jewelry vision to life.