Do you have a brilliant custom jewelry design, but then you’ve hit the wall because of the high MOQ manufacturers set? This can be very disheartening, especially if the jewelry design is unique and has the capacity to make you stand out amongst competitors.

Why is jewelry MOQ high? There are a number of factors that influence this. Join us as we shed light on the 3 main reasons behind high MOQs and professional tips on how to explore the loopholes to your advantage.

MOQ Impact on Your Jewelry Business

What is MOQ in manufacturing? It’s basically the minimum order quantity that the manufacturer says you can purchase for a product. Would you prefer a high custom jewelry MOQ or a low MOQ jewelry manufacturer? Compare how they affect your jewelry business:

| Factor | Low MOQ | High MOQ |

| Unit Cost | Higher | Lower |

| Production Efficiency | Lower (extra waiting time, wasted resources) | Higher (streamlined, optimized workflow) |

| Delivery Speed | Often Slower (low priority) | Predictable & Faster (priority Scheduling) |

| Supplier Support | Limited | Dedicated team to follow |

| Inventory Risk | Risk of frequent stockouts | Risk of overstock if sales are slow |

| Market Testing Data | Less reliable, small sample size | More reliable, statistically test data |

Reason 1: Streamlining Production & Elevating Jewelry Quality

Custom jewelry minimum order quantity can influence the production process, make it faster, and enhance the jewelry quality.

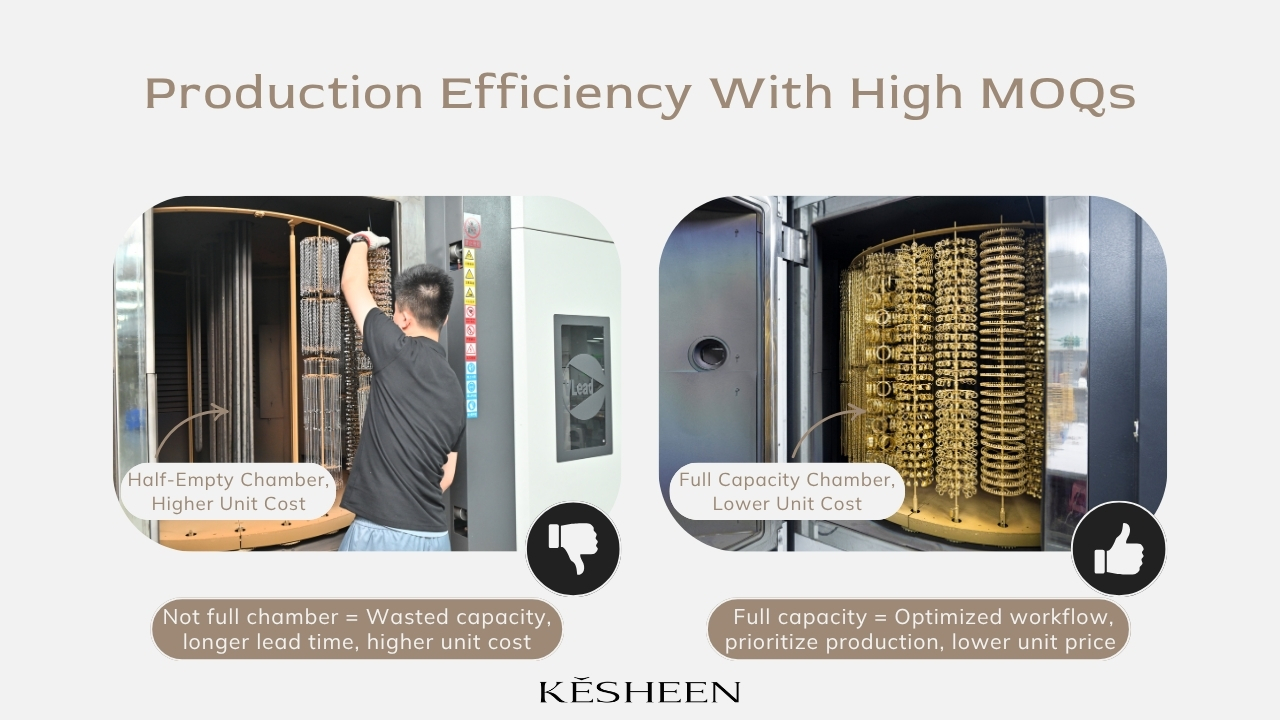

- Production Efficiency through Batch Manufacturing

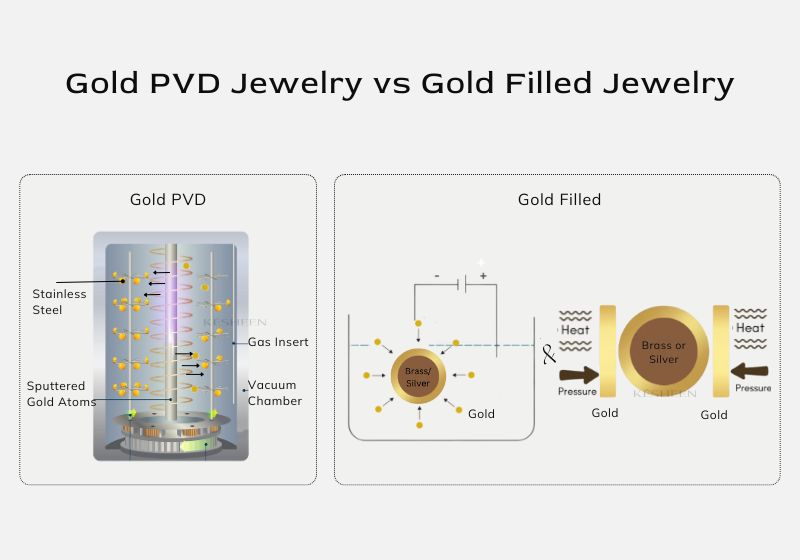

From mold preparation to final finish, high MOQ ensures that there is no downtime, no material wastage, and production is not disrupted. For example, if a PVD chamber has the capacity to produce 500 pieces of PVD coating jewelry at once, a high MOQ ensures that the chamber is fully utilized, production is completed faster, and there is no waste.

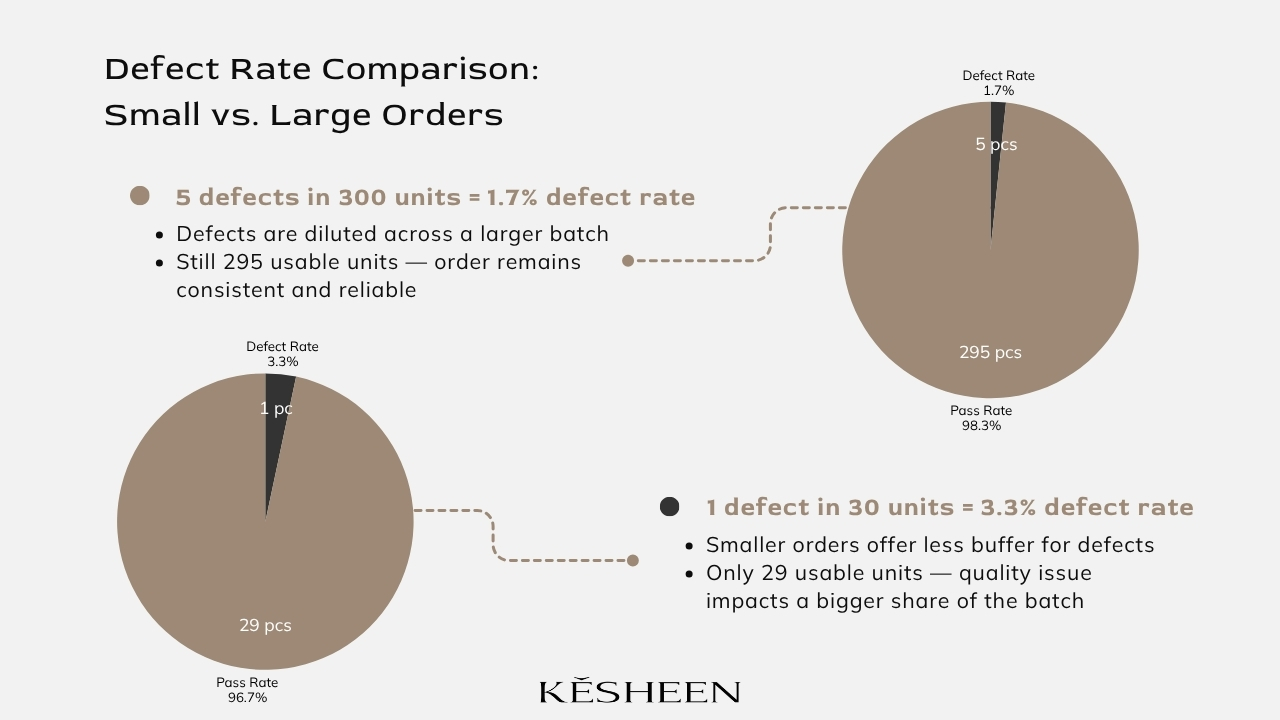

- Consistent Quality with Lower Error Rates

Producing in larger volumes allows for excellent jewelry craftsmanship and quality assurance, which minimizes variation or costly reworks. For every order, particularly complex and new molds, there’s a trial phase to check the final output and things to beware of.

This translates to lower defect and error rates during production. For example, the defects you may get in a 100-piece order is 1-3 pieces, and 1-5 pieces in a 500-piece order.

Reason 2: Reducing Per-Unit Costs & Securing Production Priority

Custom jewelry MOQ has effects on the per-unit costs and enables faster delivery timelines.

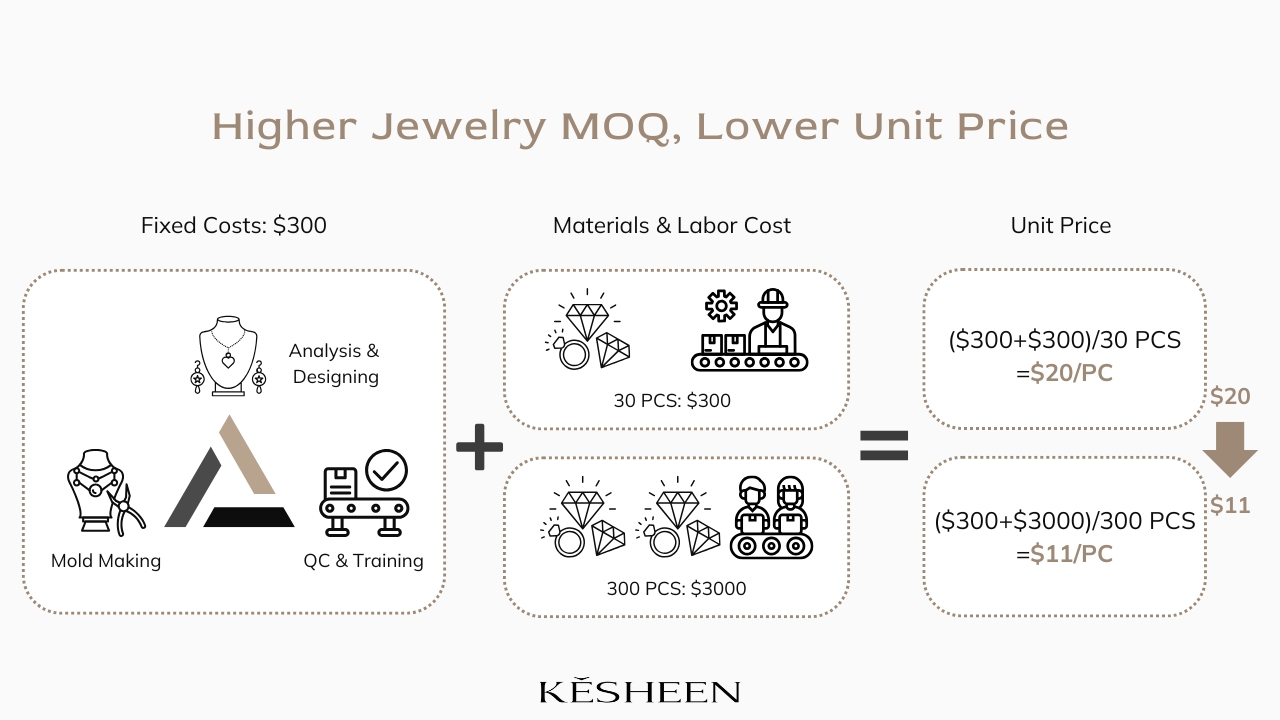

- Shared Costs with Higher MOQs to Lower Unit Price

Whether you want 100 or 500 pieces of jewelry, there are some fixed costs that remain constant, such as design, bulk material sourcing, mold making, quality control, etc. Thus, one of the jewelry-making strategies is to spread the costs across more units, reducing the price of each piece.

Manufacturers also get the opportunity to plan better for large batches, thereby reducing idle time during production.

- Faster to Market with High-Priority Scheduling

When you order in large quantities, the manufacturer will prioritize your order. This means faster production cycles and more reliable delivery schedules for your brand, allowing you to meet customers’ demands quicker than your competitors.

In fact, a special team of staff will be dedicated to you for project management, ensuring optimal quality on your order from concept to final production.

Reason 3: Testing Market Demand & Capturing Market Opportunity

Having a large quantity of products available allows you to test market demand and tap into opportunities quickly.

- Ensure a Healthy Business Model & Improve Inventory Planning

What affects MOQ in jewelry is inventory planning. Excelling in the jewelry industry is beyond having great designs—you need to have sufficient products always to meet customers’ demands, especially when you start jewelry marketing. For example, if your business average sale per day is 5 pieces of stainless steel jewelry. That means you will be selling approximately 150 pieces per month. Thus, you will need about 450 pieces on hand for the next 3 months.

Ordering in larger volume ensures that you don’t go out of stock. Remember, manufacturers normally give priority to brands with higher MOQ, so if you come every month with a low MOQ, your order will take longer time to be delivered, meaning you won’t have any product for customers.

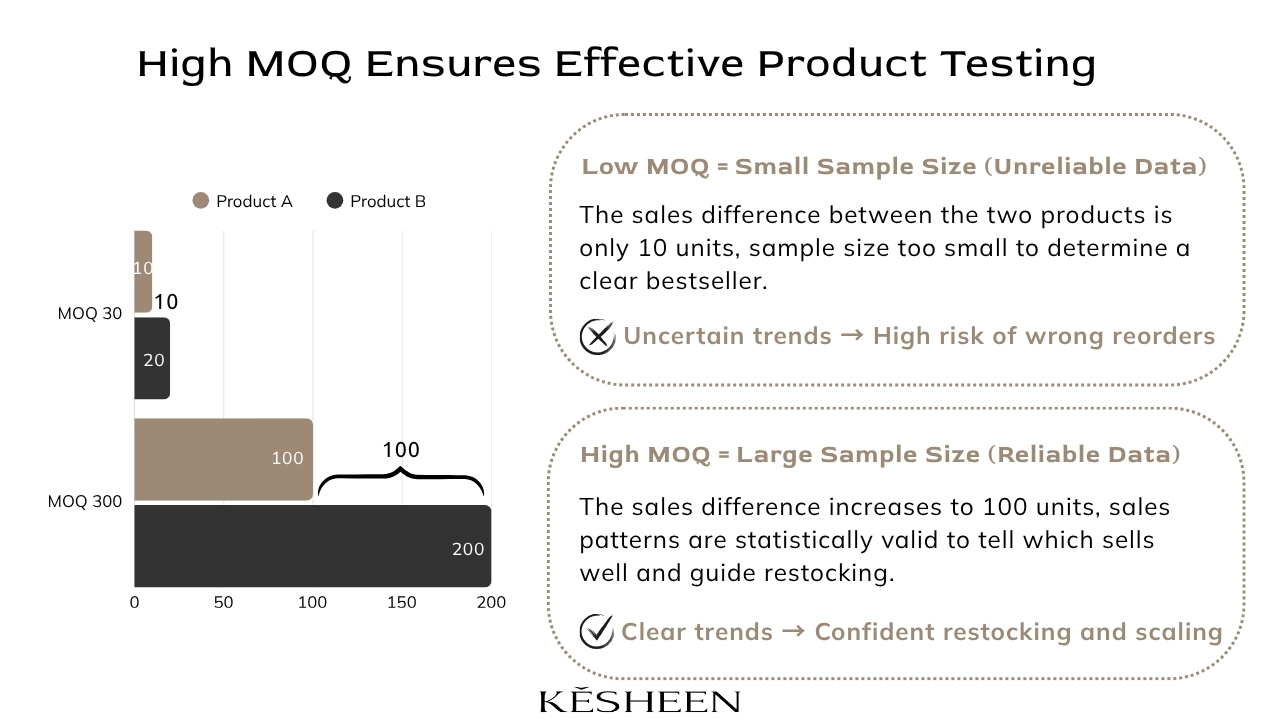

- Validate Market Demand with High MOQ Orders

Think of high MOQ as a strategy to make informed decisions. Having large volumes of two products can help you know which is performing well so that you can push more resources towards it.

Let’s say you sell Product A and Product B. If you produce 300 units of each product, and A sells 100 units while B sells 200 units, you have a clear difference of 100 which tells you that customers prefer Product B.

On the other hand, if you produce 50 units of each, and A sells 30 units while B sells 40 units, the difference is 10 which is not convincing data to prove what customers really like.

- Reduce Hidden Costs: Time, Energy & Opportunity

Some best practices for optimizing your jewelry inventory is to properly manage your time, energy, and opportunities. Low MOQ often results in repeated negotiations, frequent reordering, and delayed production. These all consume your time, energy, opportunities, and even affect supplier relationships.

In contrast, a larger MOQ not only simplifies the production and ordering operations, it also frees you up to focus on marketing, branding, and customer service.

Tips for Jewelry Brands to Handle High MOQ for Custom Jewelry

Don’t be swayed away with the need to buy in large quantities. Here are tips on flexible MOQ for new businesses:

1. Plan Inventory Effectively through Sales Data

As a new/small brand, it’s essential that you plan your inventories based on past sales data. You don’t have to order small quantities for all products. Analyze the sales data of the products and order in large quantities for the ones that sell faster. This will help you keep money in the business and expand.

2. Select from Mold-Ready or In-Stock Collections

If you can’t meet the high MOQ requirements, choose some mold-ready or in-stock collections from the custom jewelry manufacturer. The MOQs for these collections are usually lower. You can choose a design from the manufacturer’s collection and customize it with your logo tag or minor changes to the design.

3. Focus on 3-5 Designs & Order in Large Volume

Don’t order many designs at a time. Start jewelry business with a focus on 3-5 best-selling designs. Then, order them in large quantities to avoid spreading your budget thinly across numerous custom designs. This strategy allows you to get more favorable terms with the manufacturer, optimize production efficiency, and maintain a healthier profit margin.

Kesheen’s Low MOQ Policy: Ideal for Small and Growing Brands

At Kesheen, while we set standard MOQ, we’re committed to supporting small and growing brands. We’re open to negotiating MOQs based on your unique needs, allowing you to test the market and expand your collection at your own pace. You can benefit from our low MOQ policy if you meet the following requirements:

- Willing to cover the tooling/molding fee

- Capable of efficiently conveying your needs

- Align with Kesheen’s production schedule

- Designs ranging from simple to moderate complexity

Explore the benefits and possible risks of low MOQ to judge if this kind of low MOQ policy is right for your brand.

Conclusion

High MOQ is not a barrier, rather, it’s to help streamline production, improve jewelry quality, cut costs, and capture market opportunities. If you’re just starting a jewelry business, don’t be discouraged by the MOQ quoted by manufacturers, rather, follow the tips shared above to skyrocket your business.